Wholesale China Wall Panel Making Machine / Extrusion Machine / Production Line

Short Description:

It is used to wrapping PVC film on the surface of gypsum boards.

Product Detail

Product Tags

We have a highly efficient team to deal with inquiries from customers. Our goal is “100% customer satisfaction by our product quality, price & our team service” and enjoy a good reputation among clients. With many factories, we can provide a wide range of Wholesale China Wall Panel Making Machine / Extrusion Machine / Production Line, Teamwork is encouraged at all levels with regular campaigns. Our research team experiments on various developments in the industry for improvement in the products.

We have a highly efficient team to deal with inquiries from customers. Our goal is “100% customer satisfaction by our product quality, price & our team service” and enjoy a good reputation among clients. With many factories, we can provide a wide range of China PVC Ceiling Panel Making Machine, PVC Ceiling Panel Extrusion Machine, Our Company policy is “quality first, to be better and stronger, sustainable development” . Our pursuit goals is “for society, customers, employees, partners and enterprises to seek reasonable benefit”. We aspirate to do cooperate with all different the auto parts manufacturers, repair shop, auto peer , then create a beautiful future! Thank you for taking time to browse our website and we would welcome any suggestions you may have that can help us to improve our site.

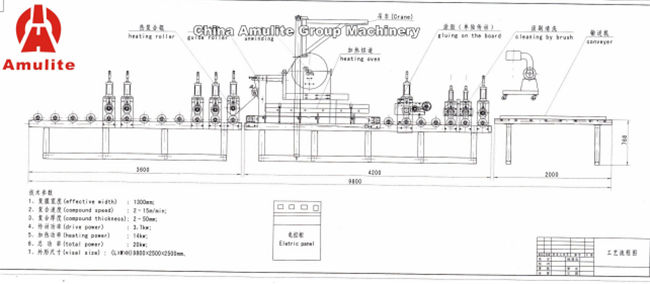

1.AM1300 Type Laminating Machine For Gypsum Boards

(it is used to wrapping PVC film on the surface of gypsum boards)

| Max. laminating width | 1300mm |

| thickness of boards | 2-50mm |

| laminating speed | 2—15m/min |

| unwinding diameter | Φ400mm, aperture Φ76mm |

| gluing method | roller coating on the boards |

| Glue type | White latex |

| heating power | 14kw |

| driver power | 3.7kw |

| total power | 20kw |

| visual size(L*W*H) | 9800*2500*2500mm |

flow chart of AM1300

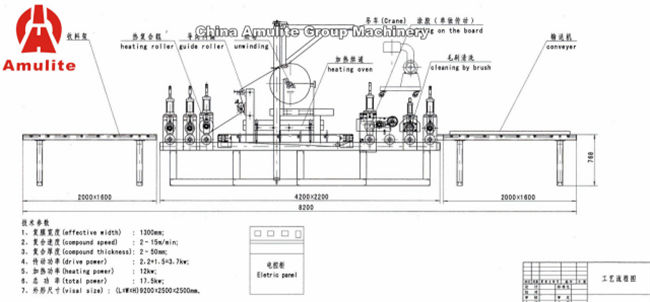

2.AM1300 Type Laminating Machine

(It is used to wrapping aluminum foil on the back of gypsum board.)

Technical parameter of AM1300

| Max. laminating width | 1300mm |

| thickness of boards | 2-50mm |

| laminating speed | 2—15m/min |

| unwinding diameter | Φ400mm, aperture Φ76mm |

| gluing method | roller coating on the boards |

| Glue type | White latex |

| heating power | 12kw |

| driver power | 2.2kw |

| total power | 17.5kw |

| visual size(L*W*H) | 9200*2500*2500mm |

Flow chart of AM1300

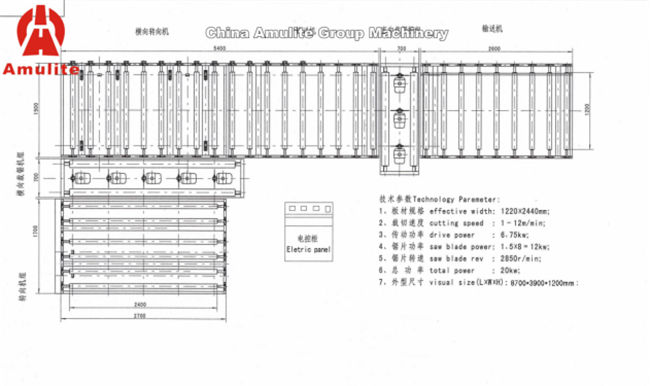

3. AM1220*2440 Type Cutting Machine for Gypsum boards

Technical parameter of cutting machine

| Effective sizes of board | 1220*2440mm |

| Min cutting sizes | 500*500mm |

| cutting speed | 2—12m/min |

| driver power | 6.75kw |

| Saw blade quantity | 8pcs |

| Saw blade power | 1.5kw*8=12kw |

| Saw blade REV. | 2850r/min |

| Power of brush cleaning | 7kw |

| total power | 27kw |

| visual size(L*W*H) | 8700*5300*1200mm |

Flow chart of AM1220*2440

We have a highly efficient team to deal with inquiries from customers. Our goal is “100% customer satisfaction by our product quality, price & our team service” and enjoy a good reputation among clients. With many factories, we can provide a wide range of Wholesale China Wall Panel Making Machine / Extrusion Machine / Production Line, Teamwork is encouraged at all levels with regular campaigns. Our research team experiments on various developments in the industry for improvement in the products.

We have a highly efficient team to deal with inquiries from customers. Our goal is “100% customer satisfaction by our product quality, price & our team service” and enjoy a good reputation among clients. With many factories, we can provide a wide range of Wholesale China Wall Panel Making Machine / Extrusion Machine / Production Line, Teamwork is encouraged at all levels with regular campaigns. Our research team experiments on various developments in the industry for improvement in the products.

Wholesale China PVC Ceiling Panel Making Machine, PVC Ceiling Panel Extrusion Machine, Our Company policy is “quality first, to be better and stronger, sustainable development” . Our pursuit goals is “for society, customers, employees, partners and enterprises to seek reasonable benefit”. We aspirate to do cooperate with all different the auto parts manufacturers, repair shop, auto peer , then create a beautiful future! Thank you for taking time to browse our website and we would welcome any suggestions you may have that can help us to improve our site.