Trending Products Fiber Cement Board Interior Wall Panels/Light Weight Wall Panels Production Line

Short Description:

Our Manufactured Fiber Cement Corrugated Roof Sheets Production Line Has Deeply Developed And Widely Used For More Than 30 Years.

Product Detail

Product Tags

Our eternal pursuits are the attitude of “regard the market, regard the custom, regard the science” along with the theory of “quality the basic, have confidence in the first and administration the advanced” for Trending Products Fiber Cement Board Interior Wall Panels/Light Weight Wall Panels Production Line, We will continue to keep operating hard and as we consider our best to supply the most effective high-quality products, most competitive selling price and exceptional company to each customer. Your gratification, our glory!!!

Our eternal pursuits are the attitude of “regard the market, regard the custom, regard the science” along with the theory of “quality the basic, have confidence in the first and administration the advanced” for China Fiber Cement Board Machine and Cement Fiber Board Machine, As an experienced manufacturer we also accept customized order and we could make it the same as your picture or sample specification. The main goal of our company is to live a satisfactory memory to all the customers, and establish a long term business relationship with buyers and users all over the world.

Our Manufactured Fiber Cement Corrugated Roof Sheets Production Line Has Deeply Developed And Widely Used For More Than 30 Years. From Hatchek And Pressed Type Corrugated Sheets Line To Current Vacuum Hatchek Forming Sheets Line Has Upgraded By 9 Times Innovation, Now Our Standard Corrugated Sheets Production Line Has Daily Capacity 10000Sq.m、15000Sq.m、 20000Sq.m For Customers’ Choice. Also We Can Customize Capacity According To Customers’ Request.

Wide Usage

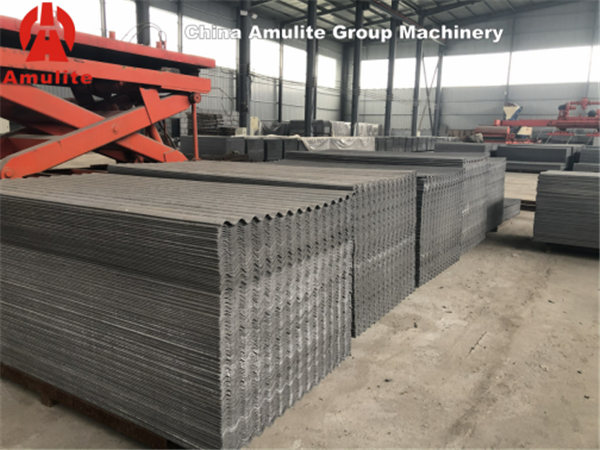

Fiber Cement Corrugated Roof Sheets Have Obvious Features Of Big Covering Area, Fireproof, Humidity Resistant, Corrosion Resistant, Heat Resistant, Light Weight Etc, And Producing Process Is Simple. Cost Low, Widely Used As Roof Sheets In Kinds Of Industrial Factories, Farming Area, Commercial Building. Residential House, Warehouse. And Temporary Buildings Etc.

Production Technology Of Fiber Cement Corrugated Roof Sheets

Cement Corrugated Roof Sheets Take Cement. Asbestos Fiber. Glass Fiber. Kraft Paper Pulp ,PVA Fiber Etc As Main Raw Materials, Adding Stone Powder Or Fly Ash. After Raw Materials Slurry Mixing Process. With Hatcheck Type Forming Sheets Line To Form Sheets. After Corrugator Corrugated To Make Final Corrugated Sheets; From Wave Difference, Normally We Make Three Types Of Wave Roof Sheets. We Call Them As Big Wave Sheets, Middle Wave Sheets. And Small Wave Sheets; For Different Countries Market, There Are Different For Waves Specification, We Can Customize Different Size Corrugated Sheets Machines According To Customer’s Market Request.

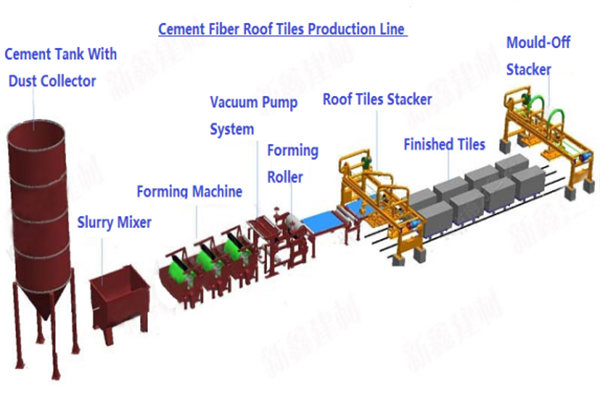

Production Process introduction

1. Slurry Storage And Mixing

Cement, Asbestos, Glass Fiber And Other Raw Materials Are Made Into Slurry By Impeller Mixing And Sent To The Sheet Forming Process Through Pipeline.

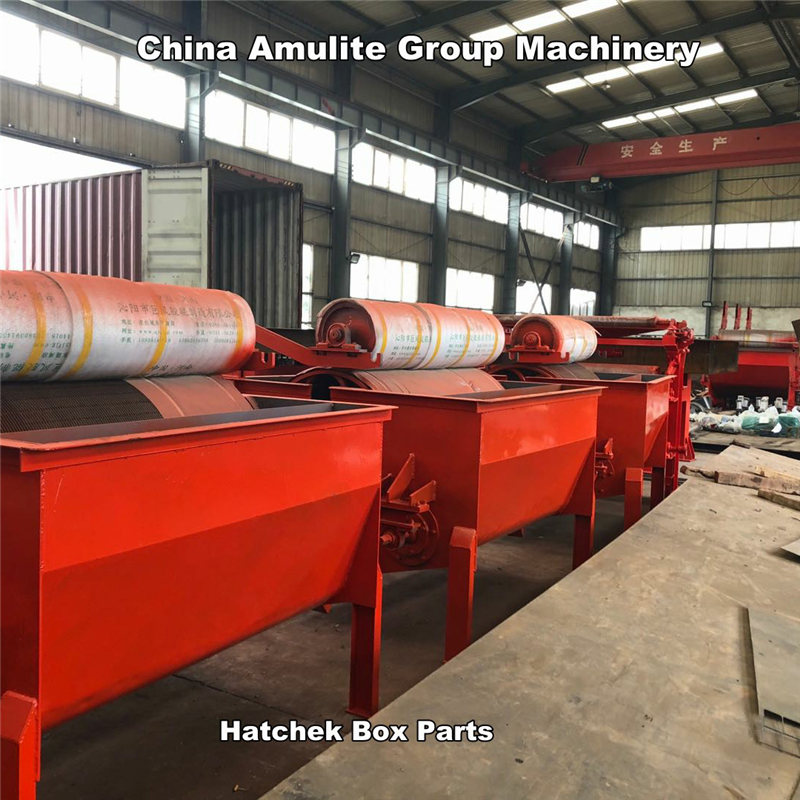

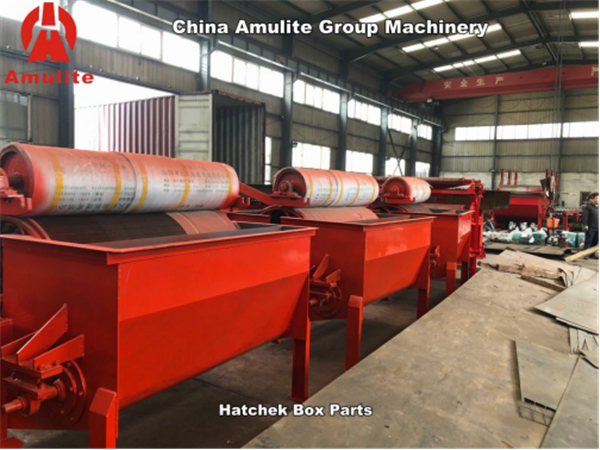

2. Hatschek Net Cage

The Moisture Of Cement Asbestos Slurry Is Discharged By Gauze Screen Isolation Method, And The Remaining Material Is Pressed Into Fiber Cement Layer By Rubber Roller.

3. Vacuum Felt Beater

Fiber Cement Slurry Layer Excess Water Is Dehydration Through Vacuum Sieve Plate,Felt Beater Will Clean Off The Dirty On The Felt ,Which Can Guarantee The Felt Running In Uniform Speed.

4. Wet Sheets Forming Machine

Under The Pressure Of The Forming Cylinder And Rubber Roller,The Dehydration Cement Asbestos Layer Is Evenly Rolled Around Forming Roller Machine, And At The Required Thickness Will Be cut By The Cutting Steel Wire Automatically.

5. Conveyor Platform Vacuum Forming Machine

After Forming Sheets From Forming Cylinder ,Fiber Cement Wet Sheets Are Conveying To Vacuum Forming Machine Through Receiving Conveyor,After Sizing And Cutting,Vacuum Forming Finish One Time,And Separate Stacking For Corrugated Sheet And Corrugated Template.

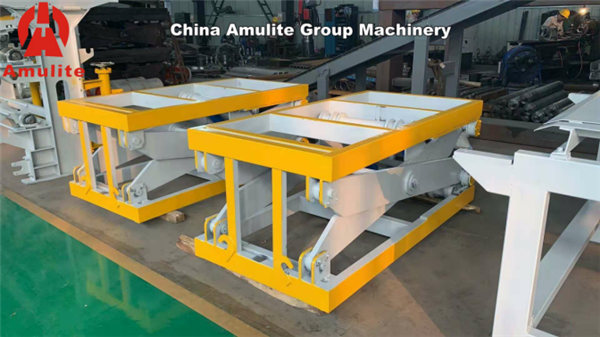

6. Hydraulic Lifting Platform

Matching With Stacker By Fully Automatic Control Modes,(Separate Action,Linkage,Lifting Up And Down,Positioning ), It Has The Characteristics Of Stable And

Accurate Lifting, Accurate Positioning ,Big Loads Etc .

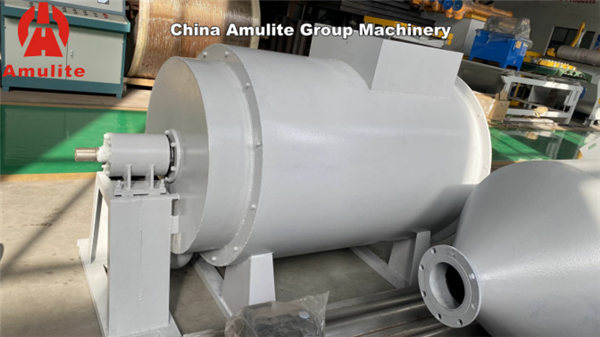

7. Paper Pulp Machine

Shredder And Refine The Wastage Paper Into Paper Pulp,Take As Raw Materials To Add For Corrugated Roof Sheet Production ;

Our eternal pursuits are the attitude of “regard the market, regard the custom, regard the science” along with the theory of “quality the basic, have confidence in the first and administration the advanced” for Trending Products Fiber Cement Board Interior Wall Panels/Light Weight Wall Panels Production Line, We will continue to keep operating hard and as we consider our best to supply the most effective high-quality products, most competitive selling price and exceptional company to each customer. Your gratification, our glory!!!

Our eternal pursuits are the attitude of “regard the market, regard the custom, regard the science” along with the theory of “quality the basic, have confidence in the first and administration the advanced” for Trending Products Fiber Cement Board Interior Wall Panels/Light Weight Wall Panels Production Line, We will continue to keep operating hard and as we consider our best to supply the most effective high-quality products, most competitive selling price and exceptional company to each customer. Your gratification, our glory!!!

Trending Products China Fiber Cement Board Machine and Cement Fiber Board Machine, As an experienced manufacturer we also accept customized order and we could make it the same as your picture or sample specification. The main goal of our company is to live a satisfactory memory to all the customers, and establish a long term business relationship with buyers and users all over the world.