Stone Hammer Crusher 6CX Euro Series Jaw Crusher

Short Description:

Product Detail

Product Tags

Brief Introduction:

The 6CX series jaw crusher is a new generation product which adopts the most advanced crushing technology and research achievements in the world and adopts the finite element analysis method on the basis of decades of experience in the design and manufacture of jaw crusher. The series products have the world’s advanced level.

Compared with the traditional jaw crusher, 6C series jaw crusher pays more attention to details in design and manufacturing, adopts high strength materials and advanced manufacturing technology, and has the advantages of higher structural strength, higher equipment reliability, larger crushing ratio, higher output, lower comprehensive processing cost and so on.

Brief Introduction:

Jaw crusher is the most commonly used crusher in the world. It has the advantages of large crushing ratio, uniform product size, simple structure, convenient maintenance and so on. It is divided into two kinds: coarse and fine. The maximum compressive strength of the crushed material is 320Mpa. The jaw crusher is my company producing fist jaw crusher is the most commonly used general random, with crushing ratio, uniform product size, simple structure of products, especially in the design and production of large jaw crusher, has been at the leading level in china.

Features:

The crushing ratio is large, the output is high, and the grain size is uniform. Simple structure and convenient maintenance. Low production cost.

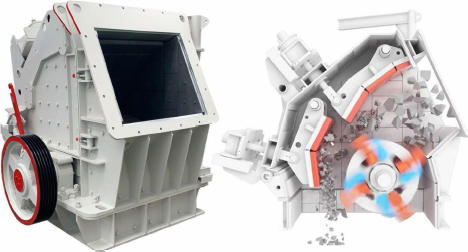

C Counterattack Crusher Series

Brief Introduction:

The C series impact crusher can realize the conversion of coarse crushing and medium fine crushing. It is suitable for all kinds of materials(granite, limestone, concrete, etc.) with strength not more than 350 MPa. And it can realize coarse crushing medium crushing and fine crushing, widely used in mining, construction, chemical industry, electric power, metallurgy and other industries.

By adjusting the installation position of the reaction frame, the conversion of coarse crushing and medium and fine crushing can be realized;

The feeding inlet is larger. It can be used as primary crusher when coarse crushing is needed, and the maximum feeding size can be up to 1000mm;

When process construction waste, it can effectively prevent steel bar from winding;

Brief Introduction:

Application

Widely used in mining, sand and gravel, water conservancy and hydropower, highway, railway, chemical industry, building materials and other industries in the crushing and plastic.

Working Principle:

The machine is a kind of crushing equipment which can use the impact energy to break the material. When the material enters the plate hammer function area, high-speed impact plate hammer the broken material constantly ran to the impact device above the rotor plate, then bounced back plate hammer area again is back again from the back lining material, from big to small in the crushing cavity repeated broken. Until the material is broken to the required size, the lower part of the machine is discharged.

Performance Characteristics:

The machine has a simple structure, no key connection, unique counter lining, high efficiency and energy saving, the product is cubic, the size of the particle size can be adjusted, the crushing process can be simplified, and the production cost can be saved.

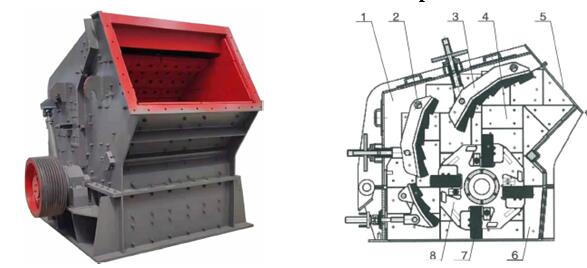

Counterattack Crusher

Brief Introduction:

PFW series impact crusher absorb the current international counterattack breaking the latest technology, giving it a new generation of the quality of the international advanced level. Rotor is the “heart” of the crusher, and it is also the most stringent part of the impact crusher. It plays an important role in the work. Therefore, the company developed and produced a strong structure of the heavy rotor to obtain a higher moment of inertia. High wear resistant material as well as the best crushing cavity, the performance of similar crusher is excellent.

Application:

The European version of this crusher is mainly used in metallurgy, mining, cement, chemical, refractories and ceramics and other industrial sectors, is widely used in highway construction, water conservancy construction, gravel, sand processing and other fields, very suitable for crushing all kinds of soft, hard ore. The coarse and medium crushing, fine crushing.

Features:

1.Adopt world-class manufacturing technology and choose the most advanced manufacturing materials.

2.heavy rotor design, as well as strict detection means, to ensure high quality of the rotor.

3. The bearing pedestal adopts integral cast steel structure. The whole cast steel bearing block can ensure the complete fit with the crushing frame, and also greatly improve the diameter of the bearing block Directional strength, which split housings do not.

4. The unique plate hammer fixing device makes the plate hammer more reliable.

5. Improved adjustment device reduces downtime and maintenance time.

6. The built-in top opening device can quickly complete the replacement of fragile parts such as plate hammer.

7. Larger bearing size and higher bearing capacity are selected.

8. Perform stress calculation and displacement analysis on the rotor to ensure stability and reliability.

Spring Cone Crusher

Brief Introduction:

PFW series impact crusher absorb the current international counterattack breaking the latest technology, giving it a new generation of the quality of the international advanced level. Rotor is the “heart” of the crusher, and it is also the most stringent part of the impact crusher. It plays an important role in the work. Therefore, the company developed and produced a strong structure of the heavy rotor to obtain a higher moment of inertia. High wear resistant material as well as the best crushing cavity, the performance of similar crusher is excellent.

Application:

The European version of this crusher is mainly used in metallurgy, mining, cement, chemical, refractories and ceramics and other industrial sectors, is widely used in highway construction, water conservancy construction, gravel, sand processing and other fields, very suitable for crushing all kinds of soft, hard ore. The coarse and medium crushing, fine crushing.

Features:

1.Adopt world-class manufacturing technology and choose the most advanced manufacturing materials.

2.heavy rotor design, as well as strict detection means, to ensure high quality of the rotor.

3. The bearing pedestal adopts integral cast steel structure. The whole cast steel bearing block can ensure the complete fit with the crushing frame, and also greatly improve the diameter of the bearing block Directional strength, which split housings do not.

4. The unique plate hammer fixing device makes the plate hammer more reliable.

5. Improved adjustment device reduces downtime and maintenance time.

6. The built-in top opening device can quickly complete the replacement of fragile parts such as plate hammer.

7. Larger bearing size and higher bearing capacity are selected.

8. Perform stress calculation and displacement analysis on the rotor to ensure stability and reliability.

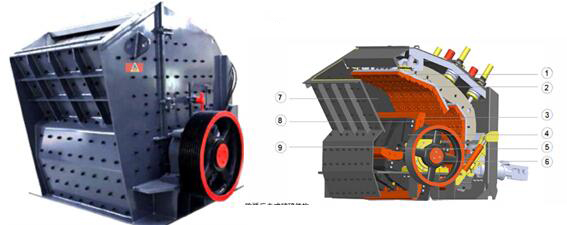

Spring Cone Crusher

Brief Introduction:

ZPC series heavy-duty hammer crusher is a new crusher developed on the basis of PC series crusher, according to user feedback information and the development trend of crushing industry, combined with the experimental data of our company. Compared with other hammer crushers, the alloy composite hammer head has the remarkable characteristics of high wear resistance, large rotational inertia and high rotor kinetic energy. It has the characteristics of large feeding size, high crushing ratio and low maintenance cost. With a production capacity of 50 to 5000 tons, this series of crushers is becoming the preferred equipment in the crushing industry.

Features:

1. The heavy hammer crusher has the characteristics of high output, low energy consumption, simple structure and convenient maintenance.

2.compared with the same output of jaw crusher, can reduce equipment investment, with less investment, effective fast.

3. The machine adopts the grate-free design, for wet materials, containing more soil broken raw materials, to eliminate the blockage of adhesion.

4.The machine adopts alloy compound hammer head, which reduces the consumption of worn parts and reduces the production cost by about 35%.