Short Lead Time for Dry Wall Gypsum Board Equipment - Gypsum Board Production Line – Amulite

Short Description:

Product Detail

Product Tags

Related Video

Feedback (2)

Short Lead Time for Dry Wall Gypsum Board Equipment - Gypsum Board Production Line – Amulite Detail:

Paper faced gypsum board production line with the annual capacity of 2 million Sq.m is the minimum paper faced gypsum board production line that manufactured in China. But small as the sparrow is, it possesses all its internal organs. It includes in all the equipments that gypsum board production line should have and has the completely technique. It has the advantages of less investment, short cycle of manufacture, immediately benefit and fast fund turnover. The land it request is not big, so it is much easier to manage and good for the environments.

Gypsum board is a kind of Pro-environment material which is know for its stable capability. Its main raw materials are natural gypsum powder and paper made from pulp, after adding the glass fiber into the slurry the good quality of the flat blank will be made. Then the flat blank will be dried in the dryer and the high quality of board will come out. It can be used in all kinds of buildings like: offices, schools, malls, living houses, stations, airports, scientific research places, restaurants, hospitals, movie theaters, gymnasiums and KTV and so on.

Paper faced gypsum board production line with the annual capacity of 2 million M2 can product all specifications of boards up to the thickness of 18mm. The boards are light with high strength.

Paper faced gypsum board production line with the annual capacity of 2million M2 is the best choice for the customer who wants invest less money and get fast benefit.

Advantages Of Gypsum Board

1. Fire-proof

Paper Faced Gypsum Board Is Grade A Incombustible Material. It Will Not Burn; Neither Produces Any Toxic Fumes Once There Is A Fire.

2. Moisture-proof

Moisture-proof Gypsum Board Has Stable Capability And Can Be Used In Bathroom.

3.High Strength

Glass Fiber Is Added Into The Raw Materials Of The Paper Faced Gypsum Board To Make It More Solid And Reliable And Not Easy To Be Broken. It Is A Good Material For Earthquake Resistance Construction And Reduces The Cost Of The Groundwork And The Main Body Of The Building.

4.Stable Size

We Adopt The Advanced Formula To Produce The Board. The Ability Of Absorption Of Moisture And Evaporation Will Be In The Optimal Range.

5. Will Make You A Comfortable Living Condition

Paper Faced Gypsum Board Is A Kind Of Construction Material With High Air Permeability And Can Adjust The Moisture In The Air. It Is Insulative And Is A Good Material For Wall.

6.Easily be installed

Paper Faced Gypsum Board Can Be Nailed, Planed, Sawed And Plastered. The Minimum Thickness Of The Wall Can Be 74mm And Can Save A Lot Of Space. Keel Will Be Used In The Installation Of The Board And Make It Very Easy.

7. Wear well

The Gypsum Board Has The Capabilities Of Stable, Acid And Alkali-resistant And Incorruptible. It Cannot Be Ruined By Moisture, Bugs Or Ants. It Can Be Used In A Very Long Time.

8. Pro-environment

There Is No Harmful Material Nor Radiation In The Paper Faced Gypsum Board. It Can Be Used In All Kinds Of Buildings.

Whole Feeding Processing System

Loading Papers

Feeding Gypsum Powder Slurry And Cover Paper Forming Board System

Gypsum Board Solidify Conveyor,Automatic Cutting And Drying System)

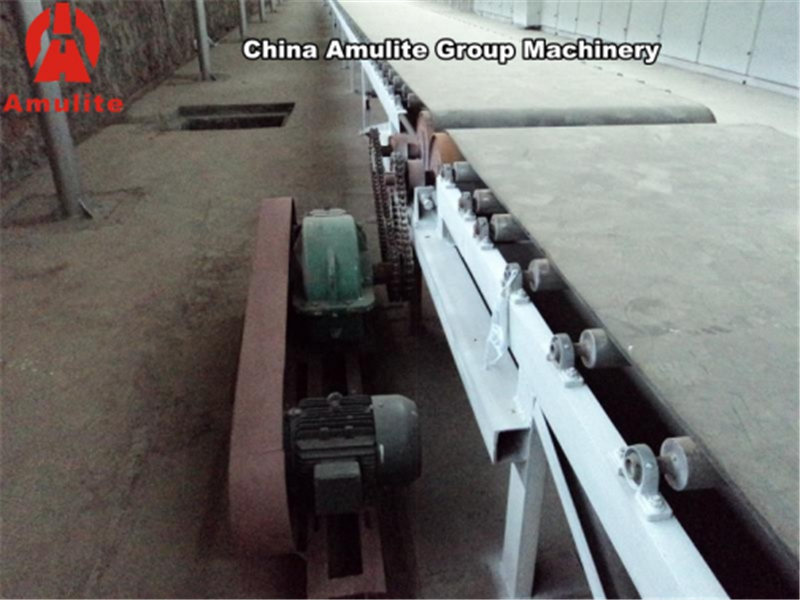

Gypsum Board Solidify Conveyor

Gypsum Board After Cutting Conveyor

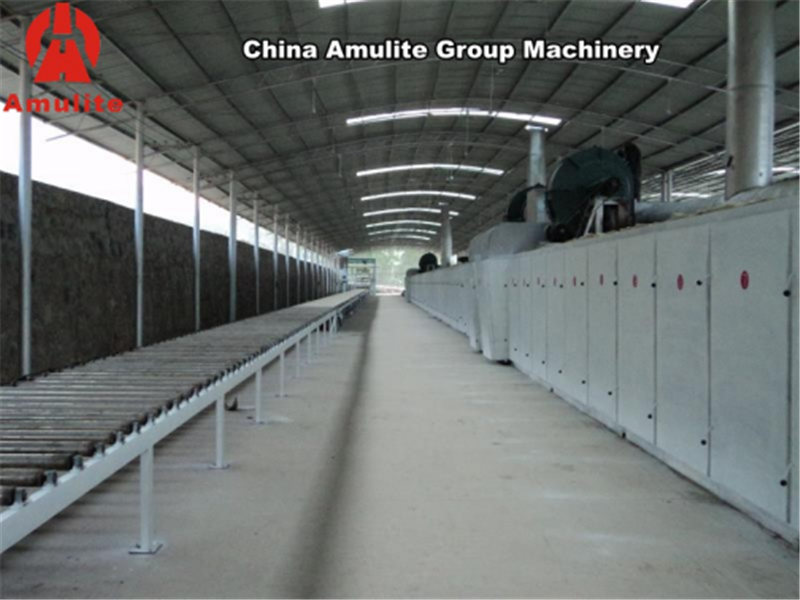

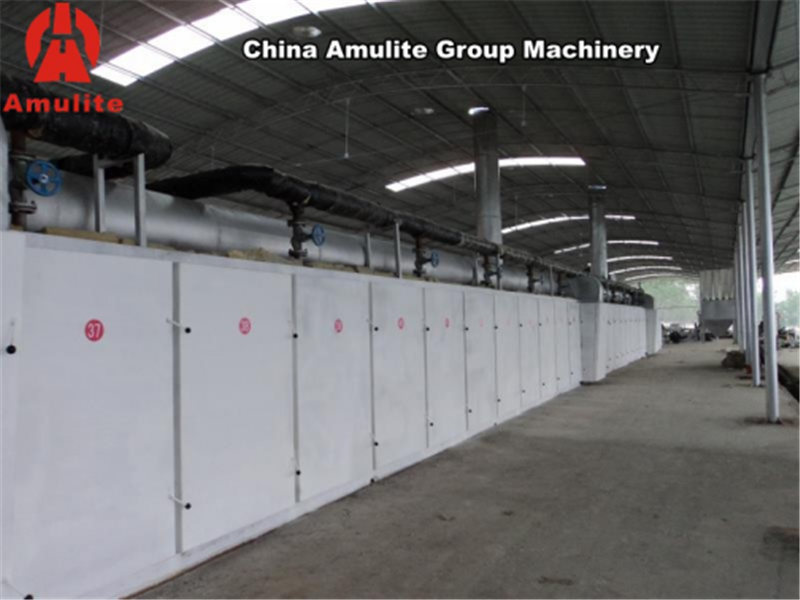

Gypsum Board Drying System

First Cross Convey System

Gypsum Board Out Of Drying Room

Gypsum Board Production Line Second Cross Convey System,Automatic Edge Cutting And Dust Collect

Electric -PLC System

Product detail pictures:

Related Product Guide:

With our leading technology at the same time as our spirit of innovation,mutual cooperation, benefits and development, we are going to build a prosperous future alongside one another with your esteemed enterprise for Short Lead Time for Dry Wall Gypsum Board Equipment - Gypsum Board Production Line – Amulite, The product will supply to all over the world, such as: Anguilla, Johannesburg, India, For many years, we now have adhered to the principle of customer oriented, quality based, excellence pursuing, mutual benefit sharing. We hope, with great sincerity and good will, to have the honor to help with your further market.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.