Quality Inspection for Eps Board Making Machine - EPS Sandwich Cement Wall Panels Production Line – Amulite

Short Description:

Product Detail

Product Tags

Related Video

Feedback (2)

Quality Inspection for Eps Board Making Machine - EPS Sandwich Cement Wall Panels Production Line – Amulite Detail:

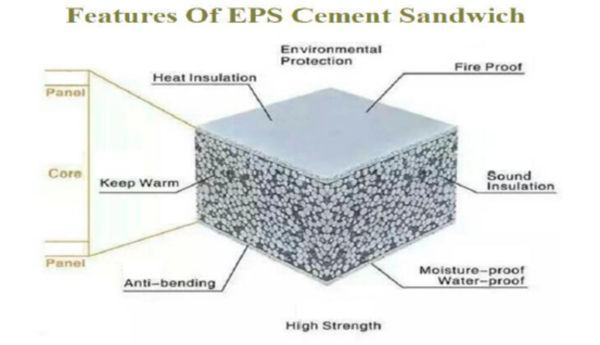

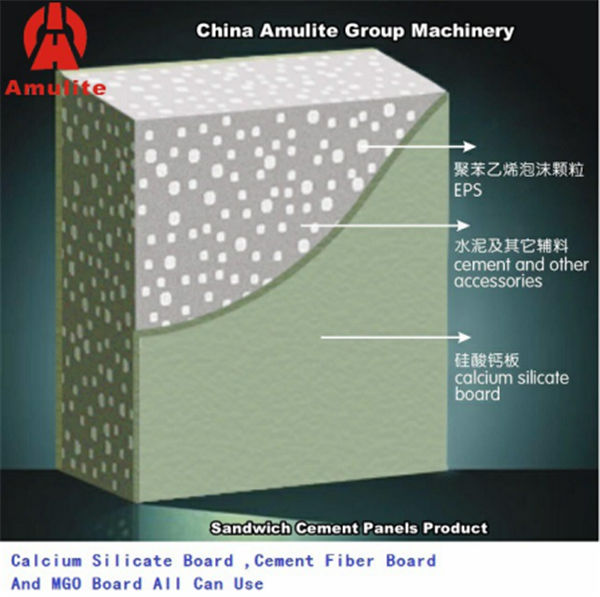

New Lightweight EPS Cement Sandwich Panels Is One New Wall Products, Which Have Good Features Of Energy-Saving ,Environmental Protection, Thermal Insulation, Sound Insulation, Light Weight, Which Make Such Product More Popular All Over The World

Production Process introduction

1.Boiler

Boiler Can Gas Generated, Oil Generated, Electricity Generated, Which Provide Steam For Plant.

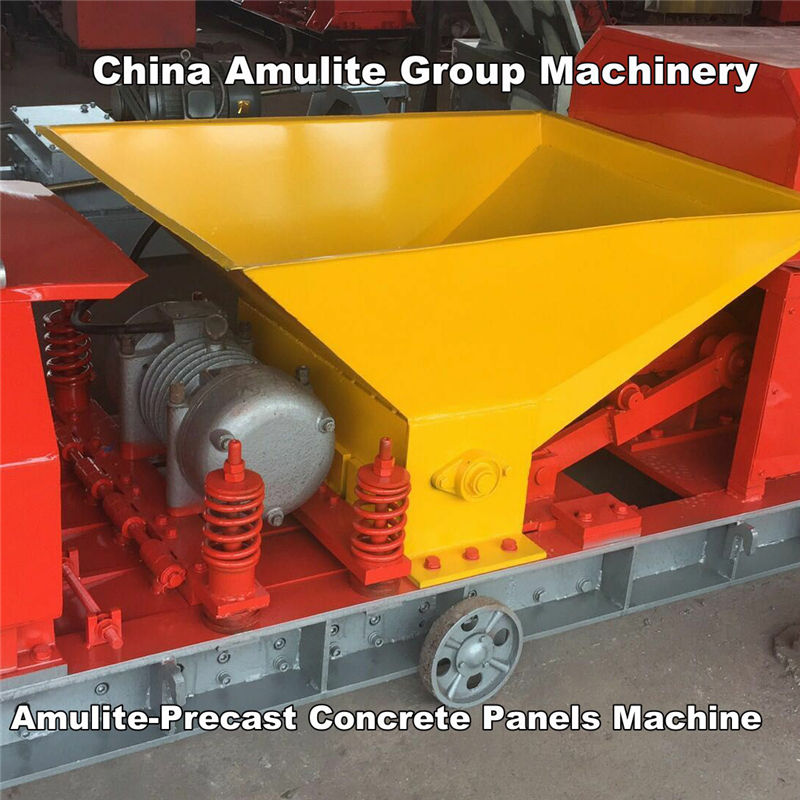

2.Mixer Platform

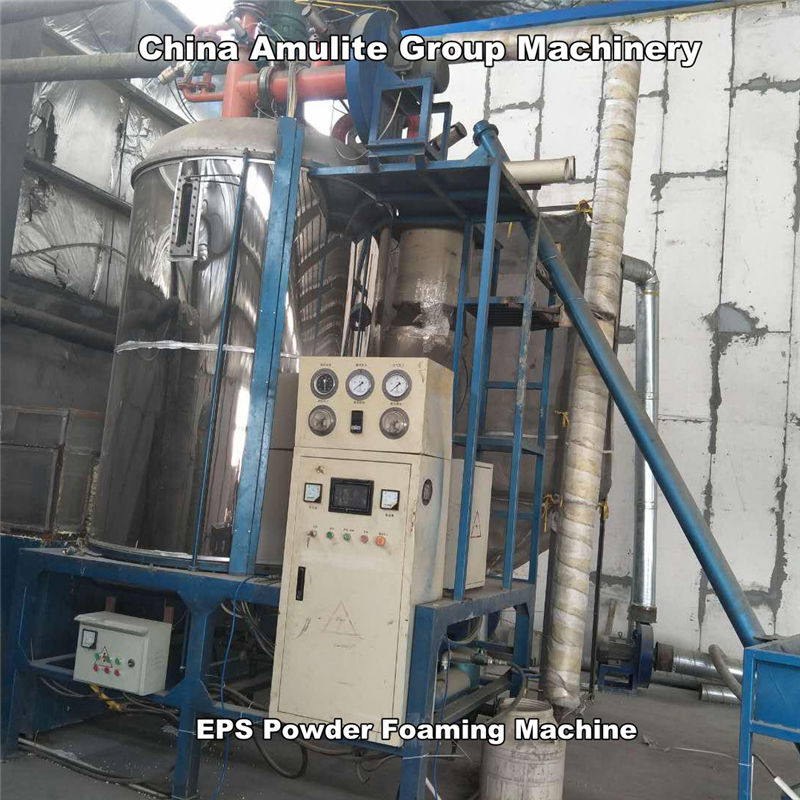

3. EPS Forming Equipment System

Including :EPS Forming Machine, Screw Conveyor, Fluidized Bed, Second Material Tank And Accessories, Mixer Head And Accessories;

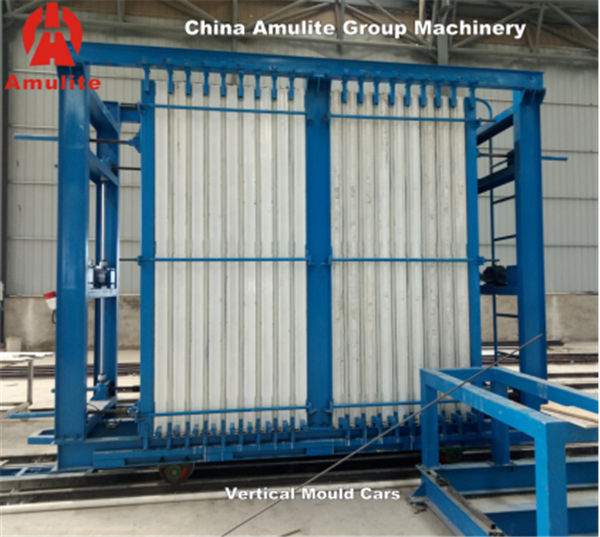

4.Vertical Wall Panel Mould Car

Vertical Panel Mould Car Can Produce 10 Pcs One Times. So The Production Capacity Is Very Higher.

5. Fully Automatically Demould Car

It Is Fully Automatically Demolding The Wall Panel. It Can Demould 5 Sheets One Time And Need About 20 Mins For One Mould Car, Which Improve The Capacity And Save Labor Cost.

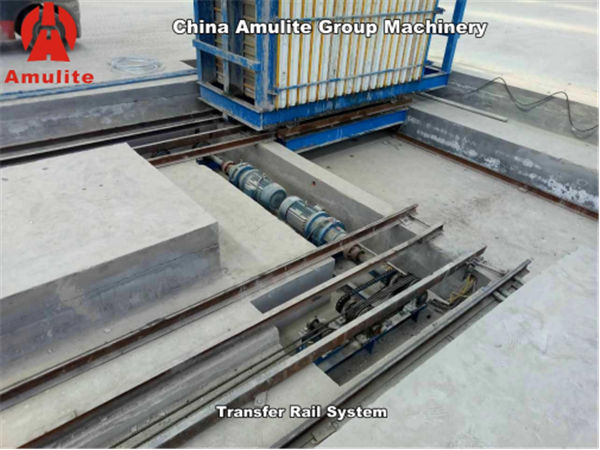

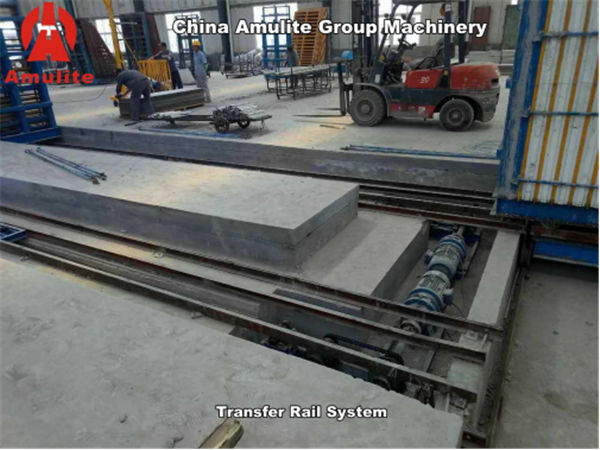

6.Automatic Transfer Cars System

Including :Traction System, Which Make Mould Cars To Move Freely Between Front And Back ; Ferry Cars System, Which Make Mould Cars Can Transfer Between Different Rails;

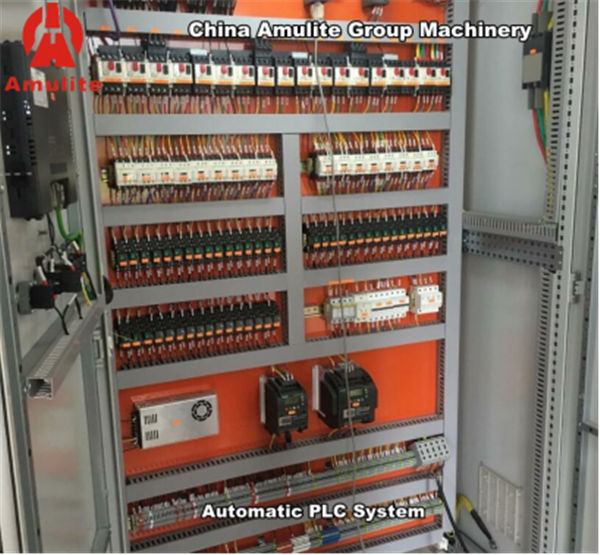

7.P LC Control Cabinet

For The Control System, We Use PLC SIMENS System With Higher Quality.

Product detail pictures:

Related Product Guide:

Our growth depends on the superior equipment ,exceptional talents and continuously strengthened technology forces for Quality Inspection for Eps Board Making Machine - EPS Sandwich Cement Wall Panels Production Line – Amulite, The product will supply to all over the world, such as: Austria, Seychelles, Indonesia, With more than 9 years of experience and a professional team, we have exported our products to many countries and regions all over the world. We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.