OEM/ODM Supplier Pu Panel For Cold Room - PVC Laminated Production Line – Amulite

Short Description:

Product Detail

Product Tags

Related Video

Feedback (2)

OEM/ODM Supplier Pu Panel For Cold Room - PVC Laminated Production Line – Amulite Detail:

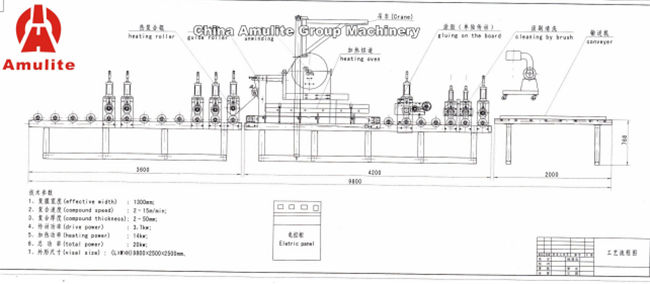

1.AM1300 Type Laminating Machine For Gypsum Boards

(it is used to wrapping PVC film on the surface of gypsum boards)

| Max. laminating width | 1300mm |

| thickness of boards | 2-50mm |

| laminating speed | 2—15m/min |

| unwinding diameter | Φ400mm, aperture Φ76mm |

| gluing method | roller coating on the boards |

| Glue type | White latex |

| heating power | 14kw |

| driver power | 3.7kw |

| total power | 20kw |

| visual size(L*W*H) | 9800*2500*2500mm |

flow chart of AM1300

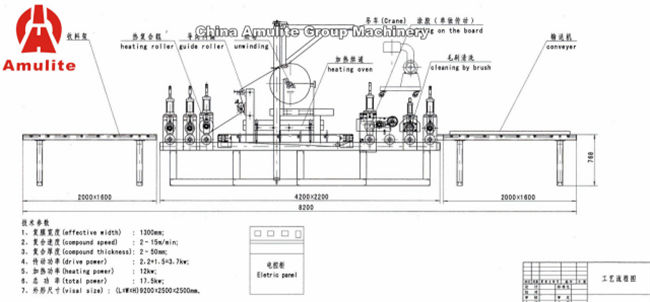

2.AM1300 Type Laminating Machine

(It is used to wrapping aluminum foil on the back of gypsum board.)

Technical parameter of AM1300

| Max. laminating width | 1300mm |

| thickness of boards | 2-50mm |

| laminating speed | 2—15m/min |

| unwinding diameter | Φ400mm, aperture Φ76mm |

| gluing method | roller coating on the boards |

| Glue type | White latex |

| heating power | 12kw |

| driver power | 2.2kw |

| total power | 17.5kw |

| visual size(L*W*H) | 9200*2500*2500mm |

Flow chart of AM1300

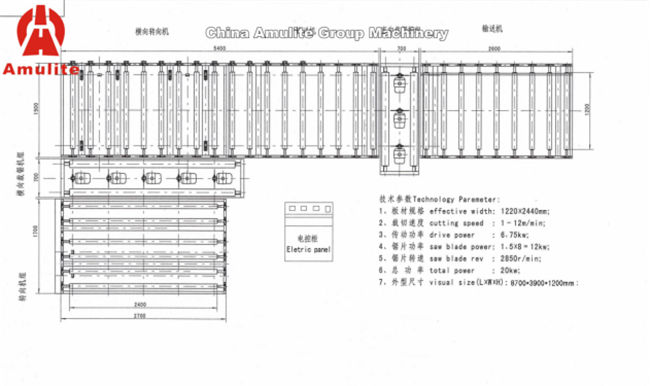

3. AM1220*2440 Type Cutting Machine for Gypsum boards

Technical parameter of cutting machine

| Effective sizes of board | 1220*2440mm |

| Min cutting sizes | 500*500mm |

| cutting speed | 2—12m/min |

| driver power | 6.75kw |

| Saw blade quantity | 8pcs |

| Saw blade power | 1.5kw*8=12kw |

| Saw blade REV. | 2850r/min |

| Power of brush cleaning | 7kw |

| total power | 27kw |

| visual size(L*W*H) | 8700*5300*1200mm |

Flow chart of AM1220*2440

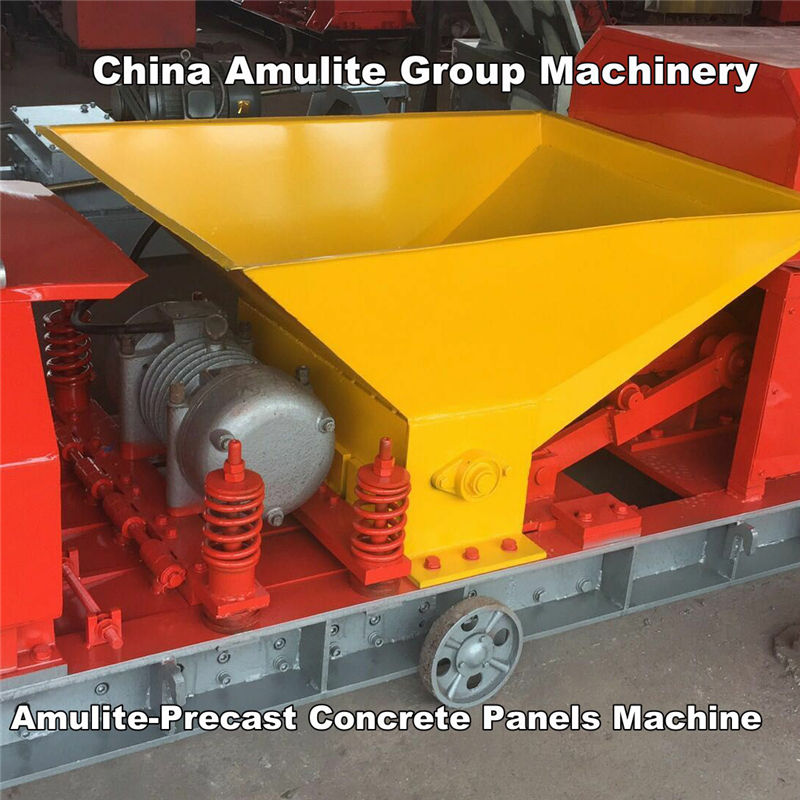

Product detail pictures:

Related Product Guide:

We follow our enterprise spirit of "Quality, Efficiency, Innovation and Integrity". We aim to create much more worth for our buyers with our abundant resources, highly developed machinery, experienced workers and great providers for OEM/ODM Supplier Pu Panel For Cold Room - PVC Laminated Production Line – Amulite, The product will supply to all over the world, such as: Mexico, Luxemburg, Sheffield, As an experienced factory we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of the company is to live a satisfactory memory to all the customers,and establish a long term win-win business relationship. For more information,please contact us. And it's our great pleasure if you like to have a personally meeting in our office.

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.