OEM/ODM Factory Uv Cured Urethane - PVC Laminated Production Line – Amulite

Short Description:

Product Detail

Product Tags

Related Video

Feedback (2)

OEM/ODM Factory Uv Cured Urethane - PVC Laminated Production Line – Amulite Detail:

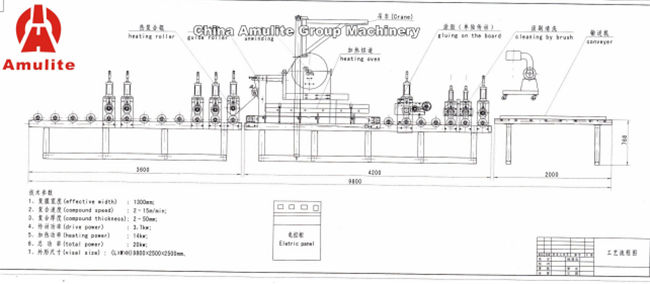

1.AM1300 Type Laminating Machine For Gypsum Boards

(it is used to wrapping PVC film on the surface of gypsum boards)

| Max. laminating width | 1300mm |

| thickness of boards | 2-50mm |

| laminating speed | 2—15m/min |

| unwinding diameter | Φ400mm, aperture Φ76mm |

| gluing method | roller coating on the boards |

| Glue type | White latex |

| heating power | 14kw |

| driver power | 3.7kw |

| total power | 20kw |

| visual size(L*W*H) | 9800*2500*2500mm |

flow chart of AM1300

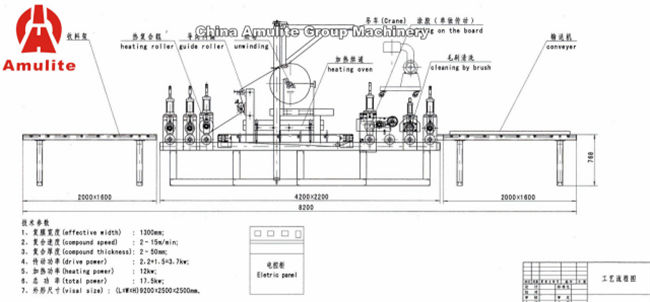

2.AM1300 Type Laminating Machine

(It is used to wrapping aluminum foil on the back of gypsum board.)

Technical parameter of AM1300

| Max. laminating width | 1300mm |

| thickness of boards | 2-50mm |

| laminating speed | 2—15m/min |

| unwinding diameter | Φ400mm, aperture Φ76mm |

| gluing method | roller coating on the boards |

| Glue type | White latex |

| heating power | 12kw |

| driver power | 2.2kw |

| total power | 17.5kw |

| visual size(L*W*H) | 9200*2500*2500mm |

Flow chart of AM1300

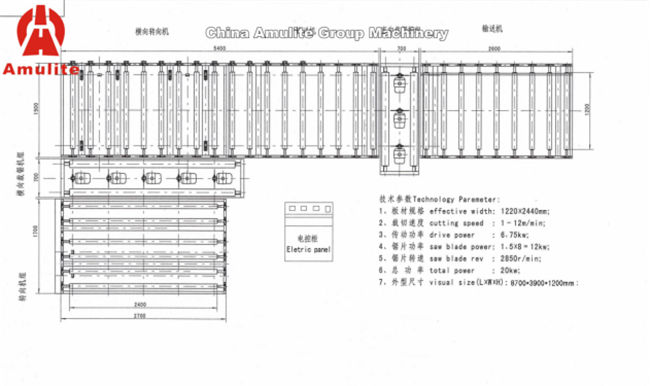

3. AM1220*2440 Type Cutting Machine for Gypsum boards

Technical parameter of cutting machine

| Effective sizes of board | 1220*2440mm |

| Min cutting sizes | 500*500mm |

| cutting speed | 2—12m/min |

| driver power | 6.75kw |

| Saw blade quantity | 8pcs |

| Saw blade power | 1.5kw*8=12kw |

| Saw blade REV. | 2850r/min |

| Power of brush cleaning | 7kw |

| total power | 27kw |

| visual size(L*W*H) | 8700*5300*1200mm |

Flow chart of AM1220*2440

Product detail pictures:

Related Product Guide:

We thinks what customers think, the urgency of urgency to act in the interests of a customer position of principle, allowing for better quality, lower processing costs, prices are more reasonable, won the new and old customers the support and affirmation for OEM/ODM Factory Uv Cured Urethane - PVC Laminated Production Line – Amulite, The product will supply to all over the world, such as: Liverpool, Malaysia, Algeria, For anyone who is keen on any of our goods right after you view our product list, please really feel absolutely free to get in touch with us for inquiries. You are able to send us emails and contact us for consultation and we shall respond to you as soon as we can. If it's easy, you may locate out our address in our web-site and come to our business for far more information of our products by your self. We are always ready to construct extended and steady co-operation relations with any possible customers in the related fields.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.