Production Process introduction

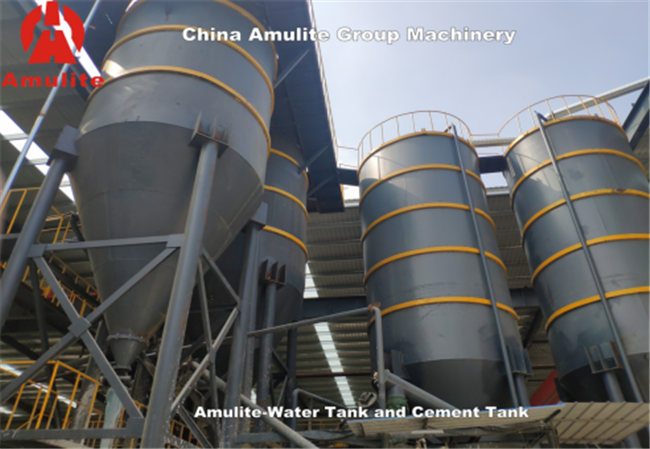

1.Water Tank And Cement Tank Process

There Is One Clean Water Tank And One Muddy Water Tank ;Both Water Tank Body Is Welded By Carbon Steel,The Muddy Water Tank Is Used To Collect Back The Recycle Water From Sheets Production Process,Muddy Water Take To Mix Into Slurry Process ,For Clean Water Tank Is Used To Take Clean Water To Clean Felt And Net Cage Normally.

2.Paper Pulp Process

Paper Pulp Process Includes Paper Shredder Machine,Refiner,And Paper Pulp Storage Tank

Paper Shredder Is Used To Shredder The Kraft Papers

Refiner Used To Grind The Paper Pulp To Be Slurry And Pumping Them To The Paper Pulp Storage Tank.

Paper Pulp Storage Tank Is Used To Store The Paper Pulp.

3. Flow-On Slurry Vacuum Water Dehydration Process

Can Choose Flow-On Slurry Forming Sheets System Or Hatschek Types Forming Sheets System To Form Sheet,We Can Customize According To Customers’ Requirement.

Well Mixed Slurry Flow Into Flow-On Slurry Box,Then From Slurry Box Convey To Running Felt To Form Slurry Layer,With Vacuum Dehydration And Chest Roller Press To Form Sheet Layer,After Layers Rolling Round Forming Sheets Drum Roller ,Then With Automatic Cutting To Form Flat Wet Sheets .

Air-Water Separator :It Is Used To Separate The Steam Water Mixture Extracted From The Vacuum Box, Flow Into The Collecting Well, And The Air Is Pumped Back To The Vacuum Pump.

4.Flow-On Slurry Sheet Forming Process

After Forming Roller Forming Sheets,Then With Automatic Laser Positioning And Cutting ,Whole PC Of Wet Sheets Go Into Convey Process.

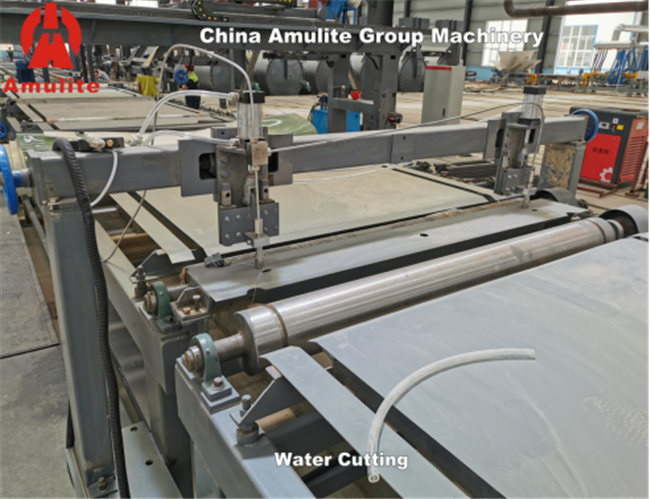

5.High Pressure Water Cutting System

This High Pressure Water Cutting System Is Our Own Patent Equipment,With Imported High Pressure Water Pump To Make High Pressure Water To Make Tidy Cutting Of Wet Sheets On Conveyor.

6.Forming Wet Sheet And Wet Sheet Conveying Process

This Process Is Used To Convey The Cut Well Wet Sheet From Forming Roller Convey The Wet Sheets To Position And Make Automatic Edge Cutting .

7. Automatic Stacker

Two Sheets Can Be Stacked At One Time. The Suction Cup Sucks Up The Wet Sheets From Receiving Conveyor machine And The Template On The Trolley At Another Working Position, And Then Stacks Them On The Trolley At The Middle Position(With The Vacuum Suction Of High-Pressure Fan). The Accurate Movement Of The Suction Cup Is Realized By The Gear On The Swing Arm Pushed By The Hydraulic Push Rod.

PLC Control, Automatic Operation.

Function: the Automatic Stacker Is Used To Sort And Stack The Quality And Inferior Products Of Fiber Cement Board/Calcium Silicate Board.

The Products Are Stacked Orderly And Highly Automated, Which Will Effectively Improve The Production Efficiency.

8 .Press Machine

Is Used To Increase The Density And Strength Of Products ,

Standard Pressure:7000ton, Press Table Size: 1350 * 2700/3200mm, Spacing: 1200mm, Working stroke: 400mm, Pressure Speed: 0.05 ~ 0.25mm/s ;

Return Speed: 15 mm / S

In And Out Of Press Transport Car: One Unit.

Power: 27.5kw

9.Trolley Traction System

Allowable Load: 20T

Table Rail Inner Distance: 750mm

Walking Mechanism:

Reducer Model: fa67-60-y-1.5, I = 50

Matching Motor Speed: 1380r / min, Power: 1.5kw

Traveling Speed Of Trolley: 9m / min

10. Vacuum Demoulding Template Machine

The Movement Of The Car And The Rise And Fall Of The Suction Cup Are Controlled By The Servo Motor.

The Demoulding Template machine Separates The Template And The Sheets On The Trolley, The Template Is Put On The Oil Brush Machine To Brush Oil, And The Sheets Is Piled On The Other Side Trolley. Add One Autoclave Interleave Spacer For Every 150 mm Sheets.

The Accurate Movement Of The Suction Cup Is Realized By The Gear On The Swing Arm Pushed By The Pneumatic Push Rod.

PLC Control, Automatic Operation.

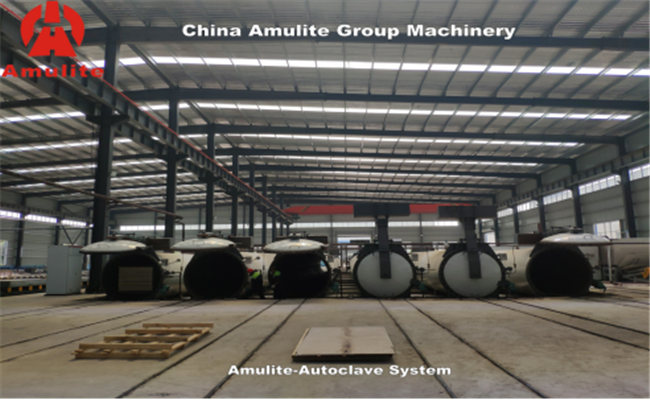

11.Autoclave Process

Due To The Characteristics Of Fiber Cement Board/Calcium Silicate Board, Lime And Quartz Sand Powder Are Used As The Main Raw Materials In The Production Process, Which Needs To Get Chemical Reaction Under High Temperature And Higher Pressure Environment,Can Let All Raw Materials Mixed Enough Well,And Make The Sheets Better Hardness And Strength.

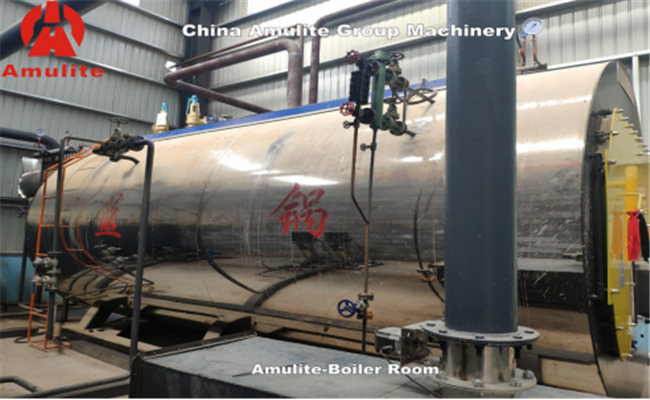

12.Boiler

In The Production Process Of Fiber Cement Board/Calcium Silicate Board,Autoclave And Dryer Are Used For Processing, And

The Heat Energy Of Autoclave And Dryer Is Supplied By Boiler!

13. Dryer

It Is Used For Drying Fiber Cement Board/ Calcium Silicate Board ,After Autoclave Curing ,The Moisture Content Of Fiber Cement Board Is About 25%. Before Sanding, Edging And Chamfering, The Moisture

Content Should Be Reduced To Lower Than 15% By Dryer. The Dryer Has The Advantages Of High Production Efficiency, Beautiful Appearance, Convenient Maintenance And Easy Operation.

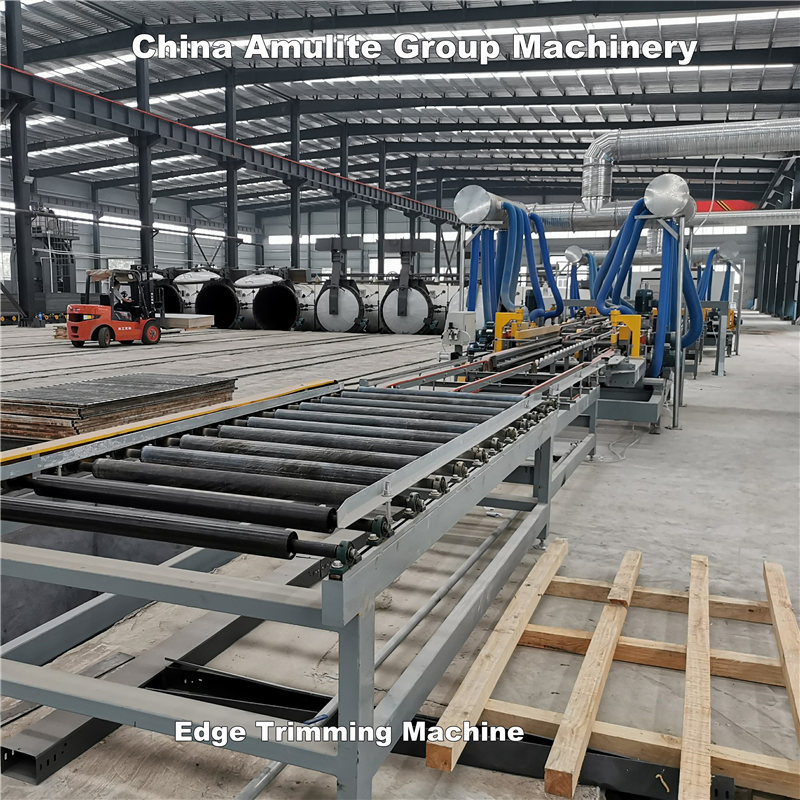

14. Edging Trimming System

Post time: Nov-02-2021