Manufacturer for China PVC Panel Forming Machine / Roof Ceiling / Plastic Wall Sheet Making Machine Production Line

Short Description:

It is used to wrapping PVC film on the surface of gypsum boards.

Product Detail

Product Tags

We attempt for excellence, support the customers”, hopes to become the top cooperation team and dominator enterprise for staff, suppliers and shoppers, realizes worth share and continual marketing for Manufacturer for China PVC Panel Forming Machine / Roof Ceiling / Plastic Wall Sheet Making Machine Production Line, We hope to establish far more organization associations with consumers all over the globe.

We attempt for excellence, support the customers”, hopes to become the top cooperation team and dominator enterprise for staff, suppliers and shoppers, realizes worth share and continual marketing for China Plastic Machine, Plastic Extruder, With a state-of-the-art thorough marketing feedback system and 300 skilled workers’ hard work, our company has developed all kinds of solutions ranging from high class, medium class to low class. This whole selection of fine items offers our customers different choices. Besides, our company sticks to high quality and reasonable price, and we also offer you good OEM services to many famous brands.

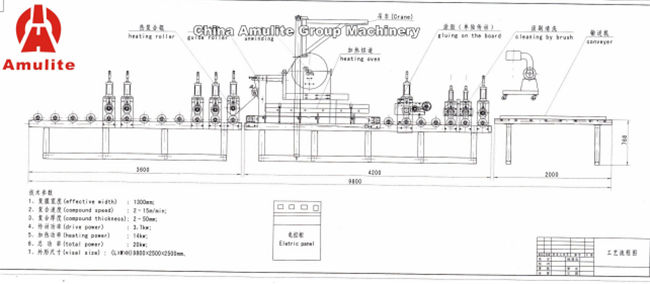

1.AM1300 Type Laminating Machine For Gypsum Boards

(it is used to wrapping PVC film on the surface of gypsum boards)

| Max. laminating width | 1300mm |

| thickness of boards | 2-50mm |

| laminating speed | 2—15m/min |

| unwinding diameter | Φ400mm, aperture Φ76mm |

| gluing method | roller coating on the boards |

| Glue type | White latex |

| heating power | 14kw |

| driver power | 3.7kw |

| total power | 20kw |

| visual size(L*W*H) | 9800*2500*2500mm |

flow chart of AM1300

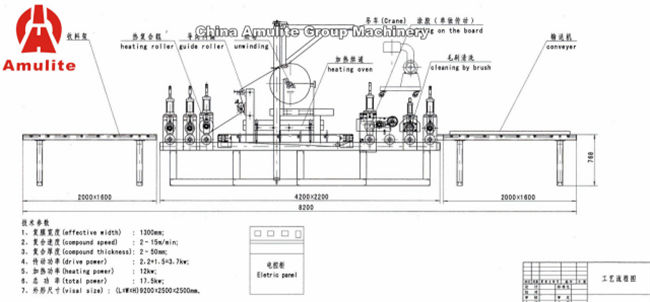

2.AM1300 Type Laminating Machine

(It is used to wrapping aluminum foil on the back of gypsum board.)

Technical parameter of AM1300

| Max. laminating width | 1300mm |

| thickness of boards | 2-50mm |

| laminating speed | 2—15m/min |

| unwinding diameter | Φ400mm, aperture Φ76mm |

| gluing method | roller coating on the boards |

| Glue type | White latex |

| heating power | 12kw |

| driver power | 2.2kw |

| total power | 17.5kw |

| visual size(L*W*H) | 9200*2500*2500mm |

Flow chart of AM1300

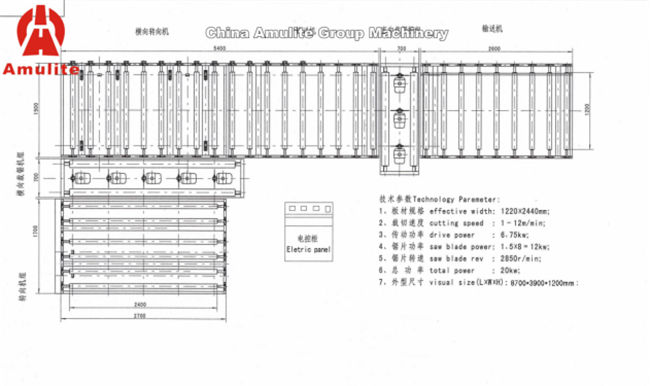

3. AM1220*2440 Type Cutting Machine for Gypsum boards

Technical parameter of cutting machine

| Effective sizes of board | 1220*2440mm |

| Min cutting sizes | 500*500mm |

| cutting speed | 2—12m/min |

| driver power | 6.75kw |

| Saw blade quantity | 8pcs |

| Saw blade power | 1.5kw*8=12kw |

| Saw blade REV. | 2850r/min |

| Power of brush cleaning | 7kw |

| total power | 27kw |

| visual size(L*W*H) | 8700*5300*1200mm |

Flow chart of AM1220*2440

We attempt for excellence, support the customers”, hopes to become the top cooperation team and dominator enterprise for staff, suppliers and shoppers, realizes worth share and continual marketing for Manufacturer for China PVC Panel Forming Machine / Roof Ceiling / Plastic Wall Sheet Making Machine Production Line, We hope to establish far more organization associations with consumers all over the globe.

We attempt for excellence, support the customers”, hopes to become the top cooperation team and dominator enterprise for staff, suppliers and shoppers, realizes worth share and continual marketing for Manufacturer for China PVC Panel Forming Machine / Roof Ceiling / Plastic Wall Sheet Making Machine Production Line, We hope to establish far more organization associations with consumers all over the globe.

Manufacturer for China Plastic Machine, Plastic Extruder, With a state-of-the-art thorough marketing feedback system and 300 skilled workers’ hard work, our company has developed all kinds of solutions ranging from high class, medium class to low class. This whole selection of fine items offers our customers different choices. Besides, our company sticks to high quality and reasonable price, and we also offer you good OEM services to many famous brands.