Free sample for Silica Sand Dryer - Precast Concrete Products Machinery – Amulite

Short Description:

Product Detail

Product Tags

Related Video

Feedback (2)

Free sample for Silica Sand Dryer - Precast Concrete Products Machinery – Amulite Detail:

1.Main Machinery

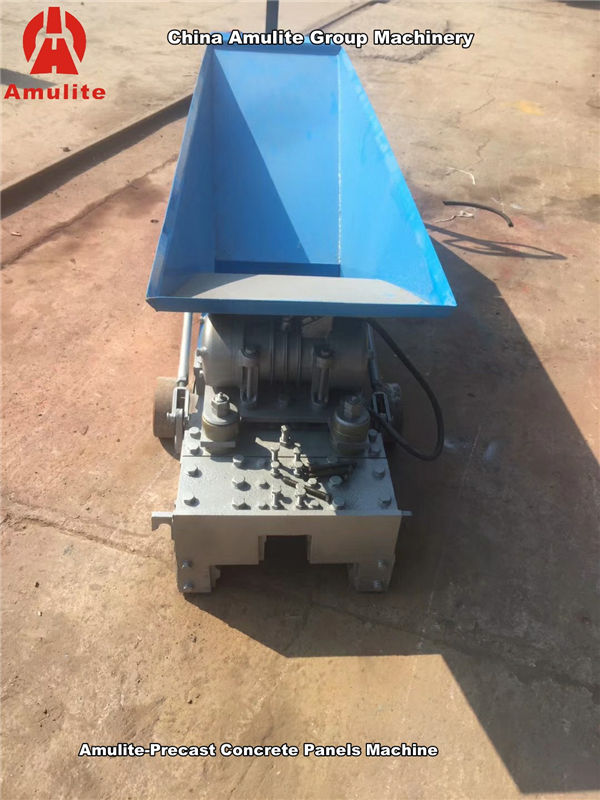

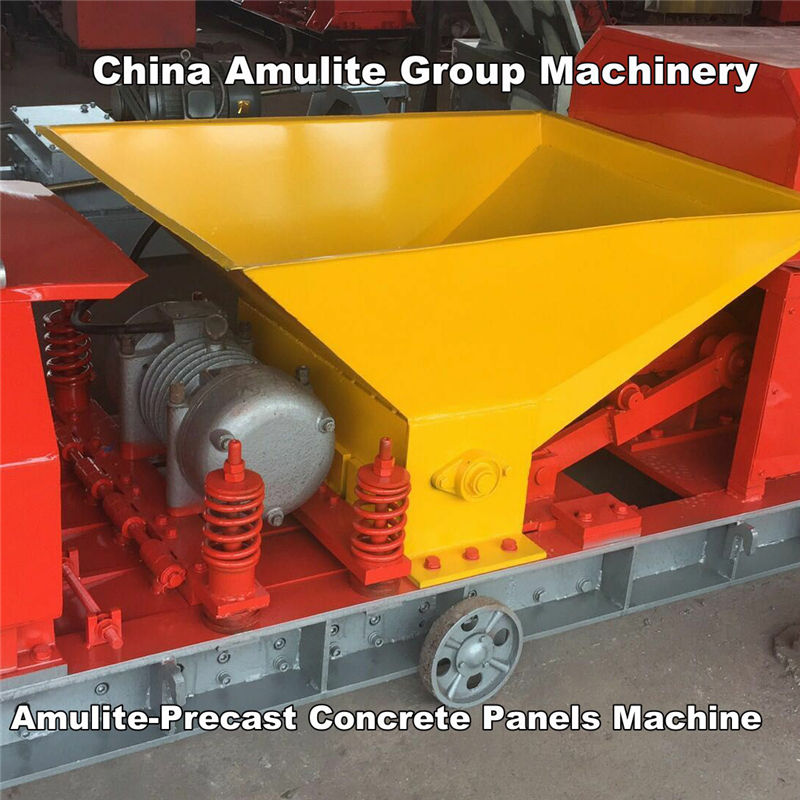

1): Precast Concrete Partition Wall Panels Machine

2): Precast Concrete L Shape, T Shape Forming Machine

3): Dung Leakage Panels Machine

4): Precast Concrete Round Hole Floor Slab Panels Machine

5): Precast Concrete Wall Panels Machines

6): Precast Concrete Thin Panels Forming Machine

7): Precast Concrete Log Passage Machine

8): Electrical Moving Dumper

9): Concrete Mixer Series

2.Precast Concrete Partition Wall Panels Advantage

1) : Resistant To Bacteria

Concrete Machine Can Resist Bacteria Increase, Smooth Surface Is Easy To Clean And Proceed Disinfection;

2) : Light Weight And Seismic Resistance

Weight Is Only 1/10 Of Red Bricks, Has Better Seismic Resistance Performance-Low Floor Building Or High Floor Building Both Can Use ;

3) : Saving Energy And Environmental Protection

During Production Process, No Need High Temperature, No Need High Pressure; For Products ,Non-Toxic, No Harmful, No Pollution, No Radioactivity, Is Green New Building Materials ;

4) : Durable And Hard-Wearing Quality

Panels Has Super Performance, Strong And Hard Surface, Bearing Weight Is Above 350KG ;Wind Resistant, Shock Resistant, High Temperature Resistant, Acid And Alkali Resistant, Corrosion Resistant, Ageing Resistant, Can Use For More Than 30 Years ;

5) : Easy Installation

Panels Can Produce According To Client’s Request, Labor Saving, Fast Installation; For Example, To Build One 756 Sq.m House, Only Needs 8 Workers, Takes 4 Days ,After Installation, Spraying Any Color Painting According To Client’s Request, More Good Looking And Choice ;

6) :Good Thermal Insulation

To Put Some EPS Or Glass Wool Inside ,Can Increase Thermal Insulation Level, Keep Warm In Winter And Keep Cool In Summer ;

7) : Lower Cost

Production Cost Is Much Lower Than Bricks ,It Is About 1/5 Of Bricks Cost ,It Is Best Choice For Easy House, Building Partition, Workshop, Warehouse Building And Breeding House;

Product detail pictures:

Related Product Guide:

With our excellent administration, strong technical capability and strict excellent control method, we carry on to offer our clients with responsible good quality, reasonable costs and great companies. We intention at becoming considered one of your most responsible partners and earning your pleasure for Free sample for Silica Sand Dryer - Precast Concrete Products Machinery – Amulite, The product will supply to all over the world, such as: Irish, Nigeria, Sheffield, On today, we've got customers from all over the world, including USA, Russia, Spain, Italy, Singapore, Malaysia, Thailand, Poland, Iran and Iraq. The mission of our company is to deliver the highest quality products with best price. We've been looking forward to doing business with you!

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.