-

Factory best selling Hollow Brick Machine - Automatic Bricks Making Production Line – Amulite

Use and characteristics 1. multi-purpose machine, It can be widely use of fly ash, slag, coal gangue, or other industrial waste and sand, stone, cement and other materials, by changing molds produce all kinds of hollow blocks and a variety of pavement brick, grass brick, Curb, standard bricks etc. 2. The machine production process using PLC automatic control, hydraulic system driven, non-contact proximity switch monitoring, mechanical, electrical, optical, liquid, high-frequency vibration tec... -

Factory For Cement Precast Concrete Production Line - PVC Laminated Production Line – Amulite

1.AM1300 Type Laminating Machine For Gypsum Boards (it is used to wrapping PVC film on the surface of gypsum boards) Max. laminating width 1300mm thickness of boards 2-50mm laminating speed 2—15m/min unwinding diameter Φ400mm, aperture Φ76mm gluing method roller coating on the boards Glue type White latex heating power 14kw driver power 3.7kw total power 20kw visual size(L*W*H) 9800*2500*2500mm flow chart of AM1300 2.AM1300 Type Laminating Machine (It is used to wrap... -

China Supplier Wrinkle Effect Uv Curing System - 1300 II Type Automatic Four Side Edge Cutting Machine – Amulite

This machine is designed by our company specially for gypsum board, wood fiber board, MGO board, Calcium Silicate Board edge cutting treatment ;For the edge cutting size ,length can be adjusted from 1830MM To 2440MM, width can be adjusted from 900MM To 1220MM,the length and width can be adjusted by setting; The Max cutting thickness is 50mm ,running stable, fast cutting, good precision, the whole cutting can be controlled by one button with air cylinder pressure, fully automatic cutting ,easy... -

OEM manufacturer Spray Paint Equipment Paint Booths - UV Coating/Painting Production Line – Amulite

(1)Base Panels:Fiber Cement Board Or Calcium Silicate Board;Base Panels Surface Is Plain. (2)Product Size:Width:1220mm,Length:2440mm,Thickness:4~30mm,Max Weight Per Pc : 100KG. (3)Product Types :According To Painting Way, This Product Is Rolling &Painting Product, Based On Different Painting Materials Can Have Four Types Of Rolling Painting And Spray Painting Products :UV Transfer Printing Series, Real Stone Painting Series, Multi-Color Painting Series, Fluorocarbon Coating Series, Wat... -

Hot sale Uv Curing Lamp Eye Protection - AM806BH-10 Technical Parameters – Amulite

Double-sided Panel Sizing Machine Parameter 1.Left And Right Slotting Saw: 2×2.2Kw 2.Left And Right Slotting Saw Cutting Saw: 2×4Kw 3.Horizontal Milling Cutter:4kW (Fixed End) 4.Adjustable Width And Narrow Motor Power:0.18KW 5.Pressing Material With Electric Lift:2×0.18Kw 6.Frequency Conversion Feeding,Motor Power 3KW,Feeding Speed 3-18m/min 7.PLC+ Touch Screen Control 8.With Cover 9.All Cutter Shafts Can Adjust The Angle And Move Forward, Backward, Up And Down Manually 10.Panasoni... -

Original Factory Cinder Block Making Machine - Automatic Bricks Making Production Line – Amulite

Use and characteristics 1. multi-purpose machine, It can be widely use of fly ash, slag, coal gangue, or other industrial waste and sand, stone, cement and other materials, by changing molds produce all kinds of hollow blocks and a variety of pavement brick, grass brick, Curb, standard bricks etc. 2. The machine production process using PLC automatic control, hydraulic system driven, non-contact proximity switch monitoring, mechanical, electrical, optical, liquid, high-frequency vibration tec... -

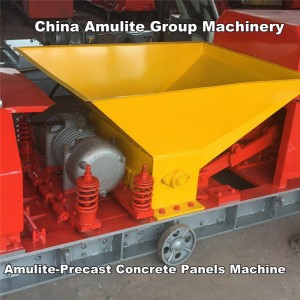

Free sample for Auger Capsule Filling Machine - Precast Concrete Products Machinery – Amulite

1.Main Machinery 1): Precast Concrete Partition Wall Panels Machine 2): Precast Concrete L Shape, T Shape Forming Machine 3): Dung Leakage Panels Machine 4): Precast Concrete Round Hole Floor Slab Panels Machine 5): Precast Concrete Wall Panels Machines 6): Precast Concrete Thin Panels Forming Machine 7): Precast Concrete Log Passage Machine 8): Electrical Moving Dumper 9): Concrete Mixer Series 2.Precast Concrete Partition Wall Panels Advantage 1) : Resistant To Bacteria Concrete Machine Can... -

OEM Factory for Digital Flatbed Uv Printer - UV Coating/Painting Production Line – Amulite

(1)Base Panels:Fiber Cement Board Or Calcium Silicate Board;Base Panels Surface Is Plain. (2)Product Size:Width:1220mm,Length:2440mm,Thickness:4~30mm,Max Weight Per Pc : 100KG. (3)Product Types :According To Painting Way, This Product Is Rolling &Painting Product, Based On Different Painting Materials Can Have Four Types Of Rolling Painting And Spray Painting Products :UV Transfer Printing Series, Real Stone Painting Series, Multi-Color Painting Series, Fluorocarbon Coating Series, Wat... -

New Fashion Design for Composite Upvc Plastic Roof Tile - Non-Asbestos/Asbestos Cement Corrugated Roof Sheets Production Line – Amulite

Our Manufactured Fiber Cement Corrugated Roof Sheets Production Line Has Deeply Developed And Widely Used For More Than 30 Years. From Hatchek And Pressed Type Corrugated Sheets Line To Current Vacuum Hatchek Forming Sheets Line Has Upgraded By 9 Times Innovation, Now Our Standard Corrugated Sheets Production Line Has Daily Capacity 10000Sq.m、15000Sq.m、 20000Sq.m For Customers’ Choice. Also We Can Customize Capacity According To Customers’ Request. Wide Usage Fiber Cement Corr... -

Quality Inspection for Uv Coating Wood - UV Coating/Painting Production Line – Amulite

(1)Base Panels:Fiber Cement Board Or Calcium Silicate Board;Base Panels Surface Is Plain. (2)Product Size:Width:1220mm,Length:2440mm,Thickness:4~30mm,Max Weight Per Pc : 100KG. (3)Product Types :According To Painting Way, This Product Is Rolling &Painting Product, Based On Different Painting Materials Can Have Four Types Of Rolling Painting And Spray Painting Products :UV Transfer Printing Series, Real Stone Painting Series, Multi-Color Painting Series, Fluorocarbon Coating Series, Wat... -

High Quality Solar Sandwich Panel - EPS Sandwich Cement Wall Panels Production Line – Amulite

New Lightweight EPS Cement Sandwich Panels Is One New Wall Products, Which Have Good Features Of Energy-Saving ,Environmental Protection, Thermal Insulation, Sound Insulation, Light Weight, Which Make Such Product More Popular All Over The World Production Process introduction 1.Boiler Boiler Can Gas Generated, Oil Generated, Electricity Generated, Which Provide Steam For Plant. 2.Mixer Platform 3. EPS Forming Equipment System Including :EPS Forming Machine, Screw Conveyor, Fluidized Bed,... -

Renewable Design for High Pressure Grinding Mill - AM806BH-10 Technical Parameters – Amulite

Double-sided Panel Sizing Machine Parameter 1.Left And Right Slotting Saw: 2×2.2Kw 2.Left And Right Slotting Saw Cutting Saw: 2×4Kw 3.Horizontal Milling Cutter:4kW (Fixed End) 4.Adjustable Width And Narrow Motor Power:0.18KW 5.Pressing Material With Electric Lift:2×0.18Kw 6.Frequency Conversion Feeding,Motor Power 3KW,Feeding Speed 3-18m/min 7.PLC+ Touch Screen Control 8.With Cover 9.All Cutter Shafts Can Adjust The Angle And Move Forward, Backward, Up And Down Manually 10.Panasoni...