-

Hot Sale for China Fiber Cement Board Calcium Silicate Sheet Making Machine Production Line

Amulite MGO Board Production Line Is An Automatic Production Line Independently Developed By China Amulite Machinery Manufacturing Group, Combined With Domestic And Foreign Market Client’s Requirement With Many Years Manufacturing Experience. -

Good Quality China EPS Concrete Wall Panel Production Line or Lightweight Hollow Core Panel Production Line

China Amulite Group ,AM-WZMZD-3000*600 Style Hollow Core Wall Panels Production Line Includes: Fully Automatic Concrete Mixing Plant, Pouring System, Automatic Wall Panel Forming Machine, Automatic Ferry Rails System, Raw Material Storage System . -

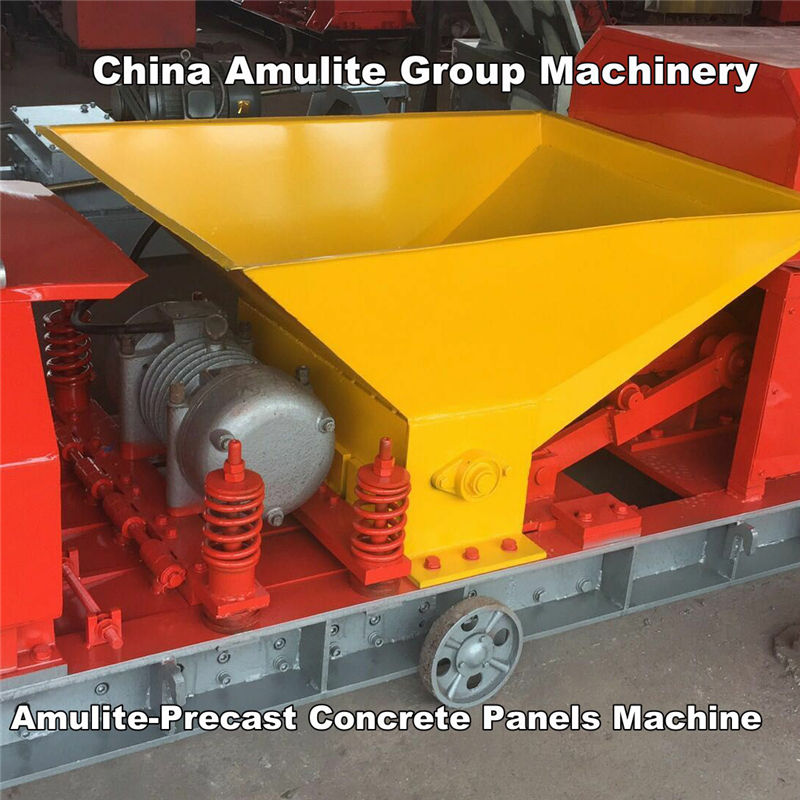

China OEM China Precast Prefab Concrete Cement Hollow Core Block Brick Paver Making Forming Machine

1): Precast Concrete Partition Wall Panels Machine

2): Precast Concrete L Shape, T Shape Forming Machine

3): Dung Leakage Panels Machine -

OEM China China Semi Automatic Hollow Clay Brick Making Machinery with Good Production Line

AM4-15C block making machine is our newly developed automatic programmable block making equipment, with the following characteristics -

ODM Factory China Automatic Professional Cement Fiber Tile Forming/Cement Roof Sheet Machine

With Fiber Cement Board Products Wide Usage In Building And Decoration Industry, -

2019 Latest Design China Residence Security Perforated Expanded Metal Wire Mesh Fence Machine

Amulite Perforated Punch Machine Is Designed To Produce Perforated Punch Panels ,Can Widely Be Used To Punch Fiber Cement Board, Calcium Silicate Board, Gypsum Board, Metal Sheets ,Wooden Panels ,MDF Panels Etc Many Kinds Of Products -

Hot-selling China High Automatic Plasterboard Gypsum Board Manufacturing Machine Production Line

Paper faced gypsum board production line with the annual capacity of 2 million Sq.m is the minimum paper faced gypsum board production line that manufactured in China. But small as the sparrow is, it possesses all its internal organs. It includes in all the equipments that gypsum board production line should have and has the completely technique. -

8 Years Exporter China EPS Sandwich Wall Panel Production Line /Lightweight Concrete Cement Panels Making Machine

Lightweight EPS Cement Sandwich Wall Panel Machine Is Manufactured According To Current Development Trend Of New Building Materials Market, Our Company Develops The New Innovation Style Of Highly Automatic Production Line, Which Can Make Waste Water Recycle And Wastage Material Reused Through Elaborate Style; Our This Plant Can Demould Automatically, Which Can Save A lot Of Labor Cost . -

Reasonable price China Energy-Saving High-Efficiency Gypsum Powder Making Machine Production Line

The crusher break the bigger gypsum stones to about 25mm smaller ones. Then the smaller ones will grinded by the grinder. -

Factory Selling China Corrugated Roof Sheet Making Machine

Our Manufactured Fiber Cement Corrugated Roof Sheets Production Line Has Deeply Developed And Widely Used For More Than 30 Years. -

Top Suppliers China Automatic UV Coating Machine UV Coating Line

Base Panels:Fiber Cement Board Or Calcium Silicate Board;Base Panels Surface Is Plain. -

Factory Supply China XPS Foamed IXPE Foam Machine Board Production Line Wps EPS Foaming Machine Plastic Foaming Machinery

I.Technical Introduction

First,compounding symmetrical1y XPS material with other assistant materialslike nucleant agent and color batch;Secondly put them into hopper of Grade Iextruder by vacuum feeder automatical1y;Thirdly melting and plasticizing resin byspecial1y designed screw symmetrically,at the same time injecting foam agent byhigh pressure and mixing it with melted resin;Fourthly,putting them into Grade IIextrusion system to meit,mix, add pressure and cool again and extruding foam boardby special mould for board, then cooling and forming board by cooling and formingdexiss..kifthly. putting the board into Grade I draw-off system and transporting theminto Grade Il draw-off system by transportation rol1s; Sixthly , cutting waste edge bysaw of both-side and finishing transverse cutting according to set 1ength; the 1ast step,stacking and storage.