Factory For Automatic Block Making Machine - Automatic Bricks Making Production Line – Amulite

Short Description:

Product Detail

Product Tags

Related Video

Feedback (2)

Factory For Automatic Block Making Machine - Automatic Bricks Making Production Line – Amulite Detail:

Use and characteristics

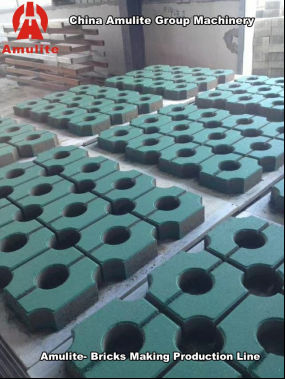

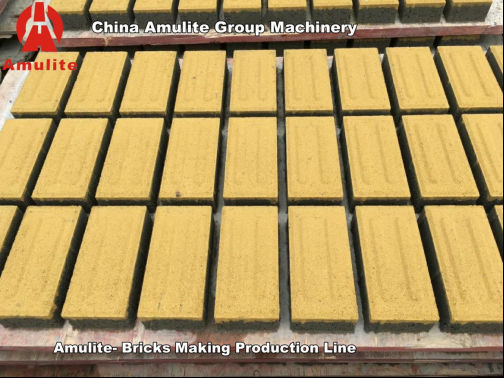

1. multi-purpose machine, It can be widely use of fly ash, slag, coal gangue, or other industrial waste and sand, stone, cement and other materials, by changing molds produce all kinds of hollow blocks and a variety of pavement brick, grass brick, Curb, standard bricks etc.

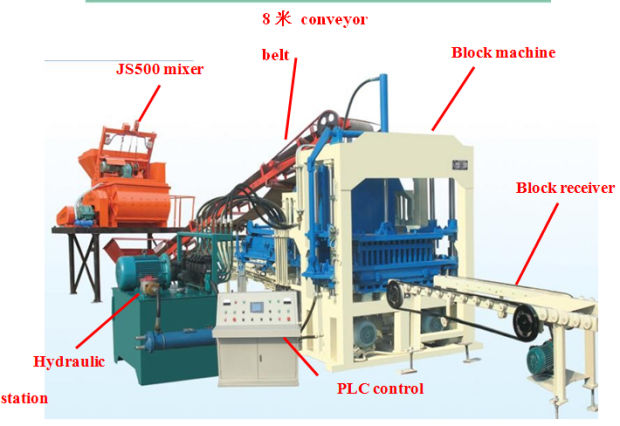

2. The machine production process using PLC automatic control, hydraulic system driven, non-contact proximity switch monitoring, mechanical, electrical, optical, liquid, high-frequency vibration technology, and carry plate, cloth, pressure vibration, stripping out brick automation, continuous and reliable operation, high production efficiency, low labor intensity operation. Durable and easy maintenance.

3. The main electrical equipment, hydraulic components are made of imported original parts or domestic brands, less failure, reliable performance

4.Block machine is based on hydraulic, supplemented by mechanical ,vibration pressurization is complete. Equipment fitted with patented vibration box, exciting force, high frequency vibration.

5. Vibration and pressure combine to make products more durable. The production of block products tensile strength up to 15Mpa (MPa) above, high density, frost resistance, impermeability, sound insulation, thermal insulation, thermal insulation performance, dimensions accurately.

6. Vibration and pressure combine to make products more durable. The production of block products tensile strength up to 15Mpa (MPa) above, high density, frost resistance, impermeability, sound insulation, thermal insulation, thermal insulation performance, dimensions accurately.

Productivity

| Hollow | block | 390×190×190mm | 4pcs/mould |

| Solid block | 240×115×53mm | 28pcs/mould | |

| Porous block | 240×115×90mm | 14pcs/mould | |

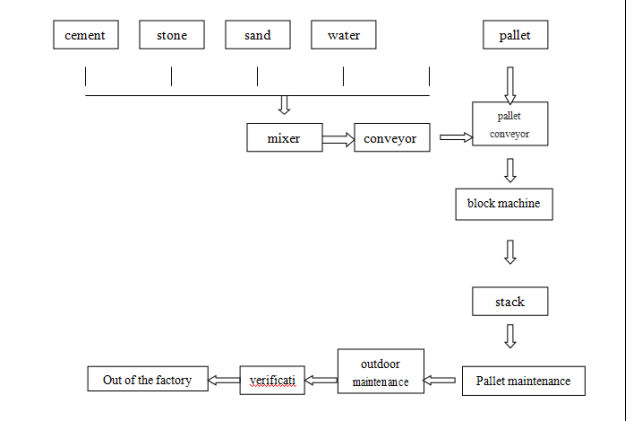

Technological Process Of Production

Product detail pictures:

Related Product Guide:

The organization keeps for the procedure concept "scientific administration, superior quality and effectiveness primacy, shopper supreme for Factory For Automatic Block Making Machine - Automatic Bricks Making Production Line – Amulite, The product will supply to all over the world, such as: Hanover, Southampton, Lesotho, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.