Factory directly 3d Wire Mesh Panel Equipment - Amulite Perforated Punch Machine System Technical Data – Amulite

Short Description:

Product Detail

Product Tags

Related Video

Feedback (2)

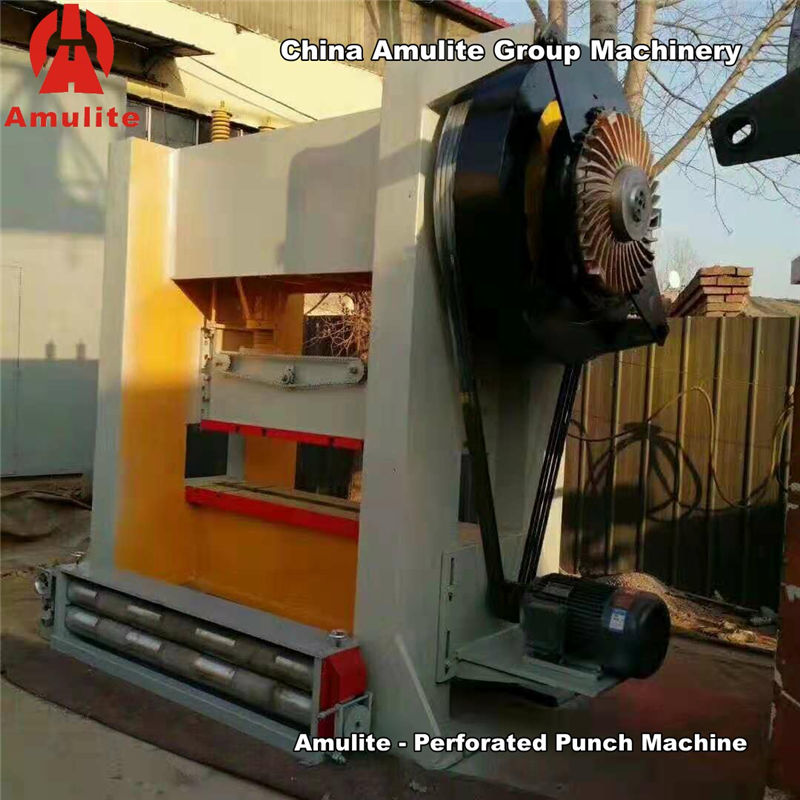

Factory directly 3d Wire Mesh Panel Equipment - Amulite Perforated Punch Machine System Technical Data – Amulite Detail:

1): Usage

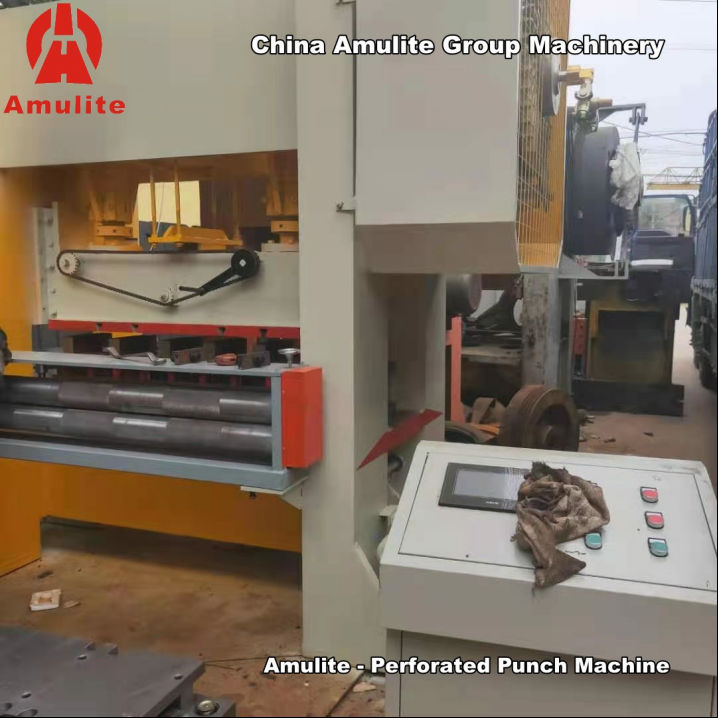

Amulite Perforated Punch Machine Is Designed To Produce Perforated Punch Panels ,Can Widely Be Used To Punch Fiber Cement Board, Calcium Silicate Board, Gypsum Board, Metal Sheets ,Wooden Panels ,MDF Panels Etc Many Kinds Of Products ;

2): Running Process

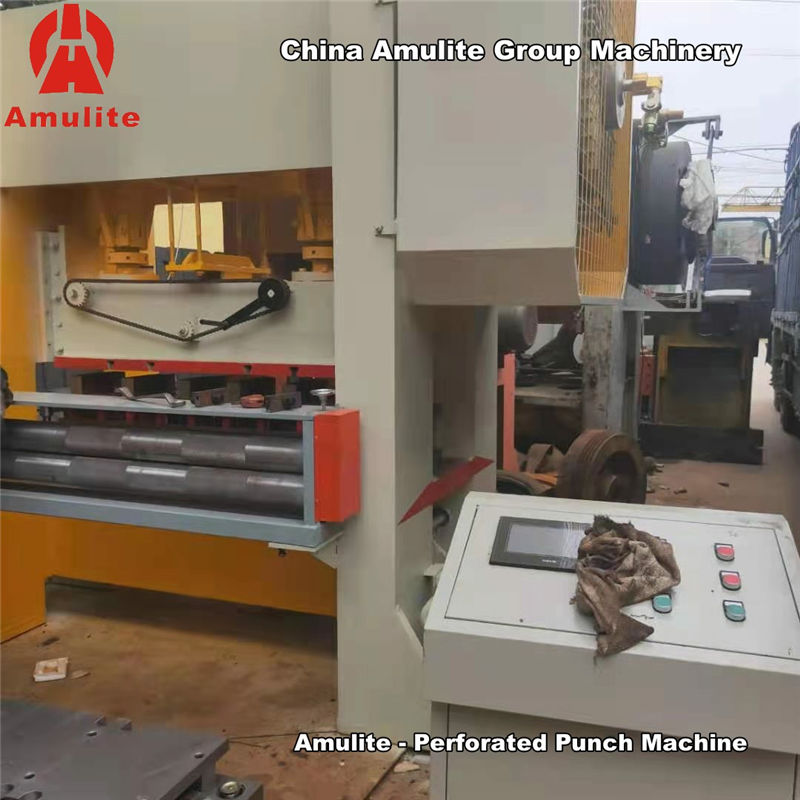

Automatic Loading -Servo Conveyor-Automatic Punching-Automatic Unloading& Stacking System

With Automatic Loading System Can Save Labor Power And Can Less Breakage Percentage Because Of Hand’s Moving, High Efficiency Design And Precise Loading And Positioning ;

Servo Conveyor Is Designed To Drive By Servo Motor, More Free Adjustment And Precise Control, Can Guarantee Smooth Panels Moving, Won’t Happen Panels Collide;

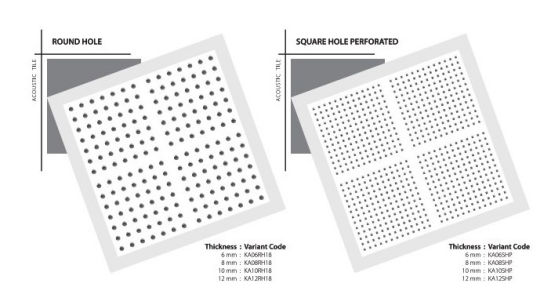

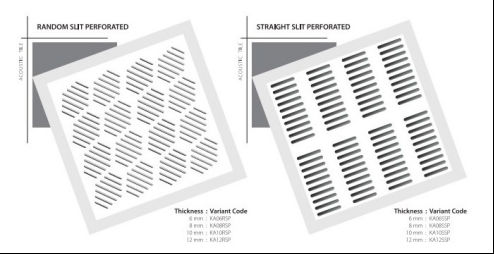

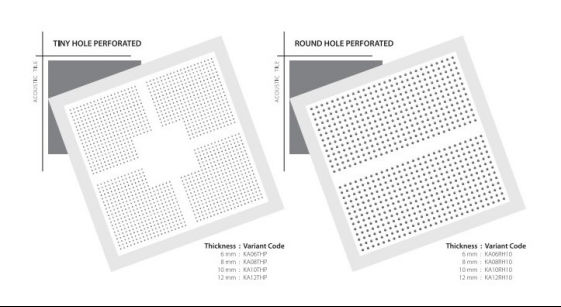

Amulite Own Designed Punching Machine And Punch Mould Can Satisfy All Customer’s Requirement For Different Designs, Round, Square, Rectangle Etc Any Shapes ,200Tons Pressure Punching System Can Make Punching In High Precision And Smooth Face ,No Damage To Panels;

Automatic Unloading& Stacking System Can Let Punched Panels Unloading And Stacking ,Laser Positioning And Tidy Stacking Which Can Save Labor And Improve Working Efficiency;

3): Technical Details

1.Working Speed: 20-30PCS Per Minute;

2.Max Size Board Allowed : 1300MM Width,2500MM Length, Can Customize Also According To Customer’s Requirement;

3.Thickness Process Limit :1MM-30MM

4.Power :22KW /11KW

5.Weight :15Tons /7Tons

6.Land Require: Width 5Meter X Length 10Meters

1): For 1.2MX2.4M Size Sheet Punch

|

No |

Item |

Specification |

Unit |

Weight |

Power |

|

1 |

Main Punch Machine |

200Tons Pressure Width 1.3M |

Set |

15Tons |

22KW |

|

2 |

Servo Conveyor |

1.3M |

Set |

||

|

3 |

Punch Mould |

1.3M Width Round Hole |

Set |

||

|

4 |

Automatic Loading |

1.2X2.4M |

Set |

||

|

5 |

Automatic Stacker |

1.2X2.4M |

Set |

2): For 0.6MX1.2M&0.6MX0.6M Size Sheet Punch

|

No |

Item |

Specification |

Unit |

Weight |

Power |

|

1 |

Main Punch Machine |

200Tons Pressure Width 0.7M |

Set |

7Tons |

11KW |

|

2 |

Servo Conveyor |

0.7M |

Set |

||

|

3 |

Punch Mould |

0.7M Width Round Hole |

Set |

||

|

4 |

Automatic Loading |

0.6X1.2M |

Set |

||

|

5 |

Automatic Stacker |

0.6X1.2M |

Set |

Product detail pictures:

Related Product Guide:

We will devote ourselves to providing our esteemed customers with the most enthusiastically thoughtful services for Factory directly 3d Wire Mesh Panel Equipment - Amulite Perforated Punch Machine System Technical Data – Amulite, The product will supply to all over the world, such as: Philippines, Roman, Bolivia, With a fully integrated operation system, our company has won a good fame for our high quality goods, reasonable prices and good services. Meanwhile, we have established a strict quality management system conducted in material incoming, processing and delivery. Abiding by the principle of "Credit first and customer supremacy", we sincerely welcome clients from home and abroad to cooperate with us and advance together to create a brilliant future.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.