2021 New Style Plastic Uv Varnish Spray Painting Line - UV Coating/Painting Production Line – Amulite

Short Description:

Product Detail

Product Tags

Related Video

Feedback (2)

2021 New Style Plastic Uv Varnish Spray Painting Line - UV Coating/Painting Production Line – Amulite Detail:

(1)Base Panels:Fiber Cement Board Or Calcium Silicate Board;Base Panels Surface Is Plain.

(2)Product Size:Width:1220mm,Length:2440mm,Thickness:4~30mm,Max Weight Per Pc : 100KG.

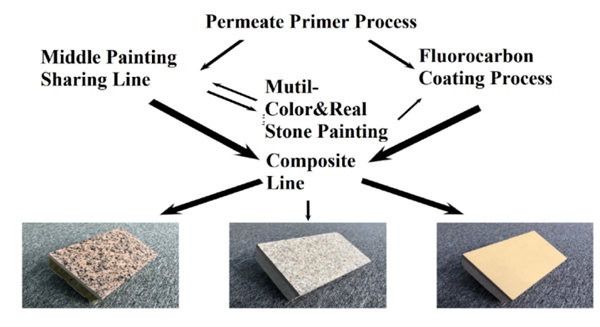

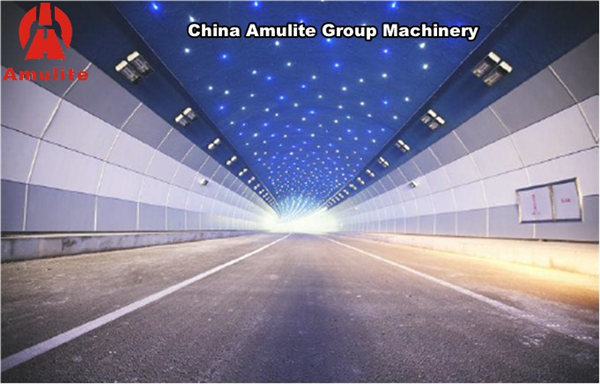

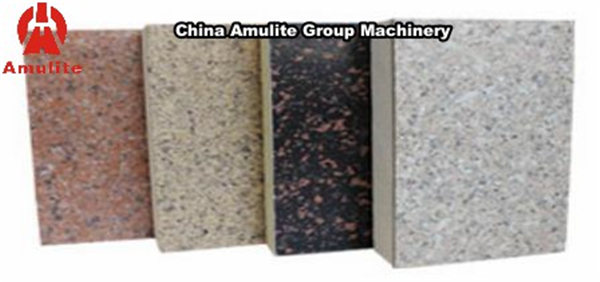

(3)Product Types :According To Painting Way, This Product Is Rolling &Painting Product, Based On Different Painting Materials Can Have Four Types Of Rolling Painting And Spray Painting Products :UV Transfer Printing Series, Real Stone Painting Series, Multi-Color Painting Series, Fluorocarbon Coating Series, Water Painting Series; All These Products Have Big Market Shares In Exterior And Interior Wall Panels.

Primer Coating Machines Technology

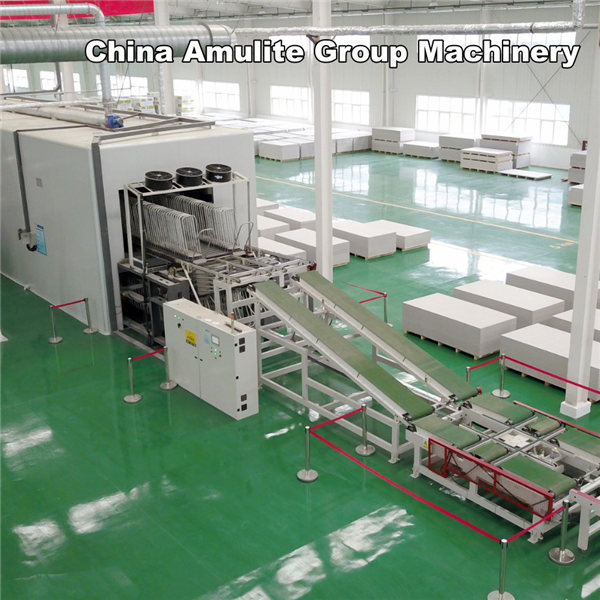

Automatic Loading Board →Board Thicknessing→Dust Collector→High Precision Double Roller Rolling Coating Machine→10M Hot Air Drying System→Double UV Light Curing→Reverse Roller →Three UV Light Curing →Board Centering→Primer Sander→Dust Collector→Reverse Roller→10M Hot Air Drying System→Three UV Light Curing→Board Centering→Primer Sander→Dust Collector→Automatic Unloading Board

Technology Features

1):When Rolling Coating UV Permeating ,Front Roller Middle Hole Sponge Roller, Back Roller35°PU Roller;2):When Rolling Epoxy Painting Permeating, Take 35° Carving &Grooving Roller, This Process Is Before Permeating Primer Water-Borne Painting; Rolling UV Putty, This Process Is To Fill Board Surface Uneven Pit And Rolling UV Sanding Primer, This Process Is Before Fluorocarbon Coating.

1.Fluorocarbon Coating/Metal Fluorocarbon Coating Product Technology

Automatic Loading Board→Dust Collector→High Precision Double Roller Rolling Coating Machine→20Meter Hot Air Drying System→Board Centering→High Precision Double Roller Rolling Coating Machine→15Meter Hot Air Drying System→Board Centering→High Precision Double Roller Rolling Coating Machine→15Meter Hot Air Drying System→Board Centering→High Precision Double Roller Rolling Coating Machine→10Meter Hot Air Drying System→Board Centering→Board Translation→Board Centering→40M Dryer→6M Cooling→Board Centering→Film Lamination&Cutting→Automatic Unloading Board

Technology Feature

Thin Rolling Coating More Times, Uniform Colors, Very Beautiful Appearance; The Environmental Requirements Of Coatings Are Relatively Low; Also Request For Base Board Is Relatively More Lower;

Save Painting And Lower Down Cost;

2.Water-Borne Medium Painting&Water-Borne Covering Painting Products Technology

Automatic Loading Board→Dust Collector→High Precision Double Roller Rolling Coating

Machine→10Meter Hot Air Dryer→Board Centering→High Precision Single Roller Rolling Coating Machine→5M Hot Air Dryer→30M Vertical Dryer→6M Cooling→Board Centering→Film Lamination&Cutting→Automatic Unloading Board

Technical Feature

Thin Rolling Coating More Times, Uniform Colors, Very Beautiful Appearance;

Avoid Out Of Other Color, Save Face Painting ;

3.Real Stone Painting&Multi-Color Painting Product Technology

Automatic Loading Board→Dust Collector→Board Centering→Real Stone Painting→Board Centering→50PCS Drying Room→Board Centering→Multi-Color Painting→Board Centering→50PCS Drying Room→40M Dryer→Automatic Unloading Board

Technical Feature

Real Stone Painting As Bottom Painting, Color Points Better Quality Feeling, Automatic Production, Higher Capacity, Popular Products In Market;

4. Water-Borne Medium Paint &Water-Borne Covering Paint Product Technology

Automatic Loading Board-Dust Collector-Gluing-Board Centering-Manual Stacking Composite Material(Rock Wool Or EPS Core)-(Loading Back Board-Dust Collector-Gluing-Board Centering-Board Turnover-Back Board Input)-Board Centering-Automatic Unloading

Technical Feature

Can Composite Insulation Core Materials By One Time, Suitable For Different Kinds Of Insulation Core Materials To Make, Flexible To Produce According To Market Demand.

Main Machine Introduction

1.Hot Air Dryer

2.Double Round Spraying System

3.High Precision Double Roller Rolling Coating Machine

4.50 PCS Drying Room

5.Dryer

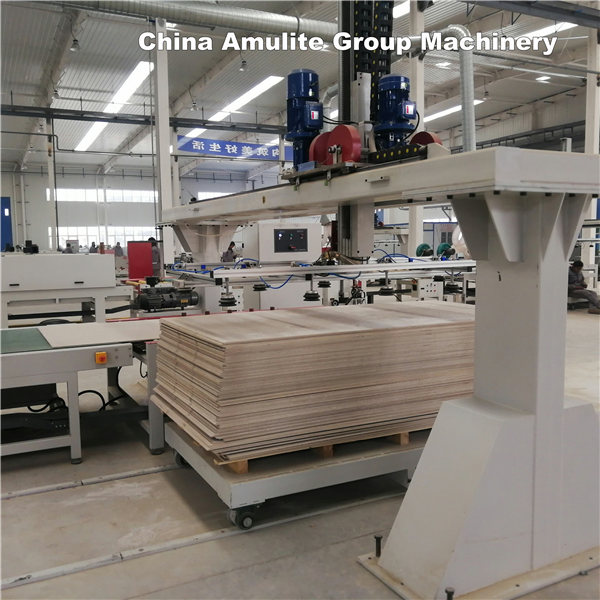

6.Gantry Loading System

Product detail pictures:

Related Product Guide:

We can constantly satisfy our respected customers with our good high quality, good price tag and good support due to we have been additional specialist and extra hard-working and do it in cost-effective way for 2021 New Style Plastic Uv Varnish Spray Painting Line - UV Coating/Painting Production Line – Amulite, The product will supply to all over the world, such as: South Korea, Egypt, Iran, Our company's main products are widely used all over the world; 80% of our products exported to the United States, Japan, Europe and other markets. All stuff sincerely welcome guests come to visit our factory.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!